Near the Dutch village IJsselmuiden stands the world’s first robot sorting and packing linΣe in cucumber cultivation. Last year, the Vahl brothers introduced this innovative robot line to improve the speed and quality of the sorting process and optimize personnel deployment.

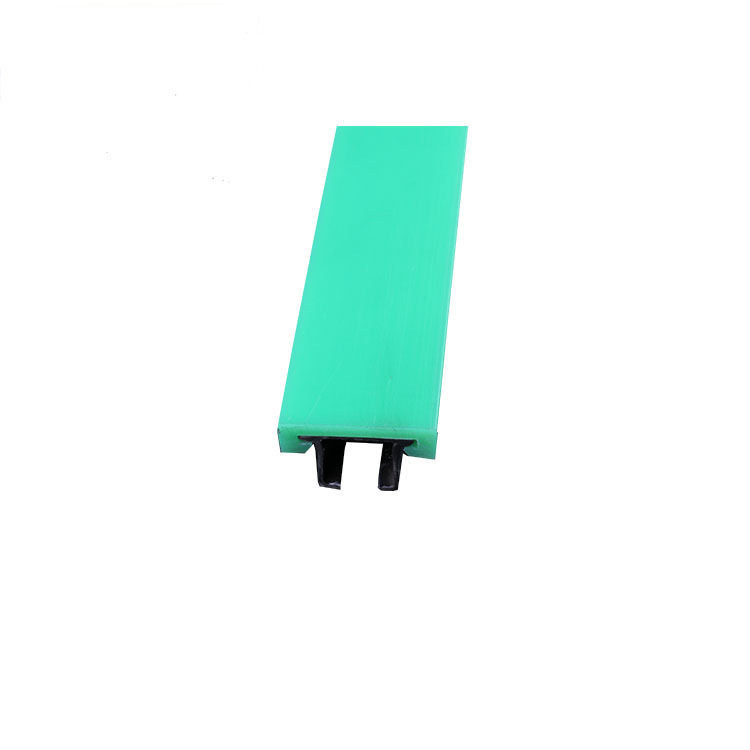

It is a dynamic spectacle to see the sorting and packing line in full action in Vahl’s processing area. It starts with manually feeding the cucumbers, according to Dutch magazine In Greenhouses. The cucumbers slide over conveyor belts towards the weighing line. After determining the weight, the machine takes 3-dimensional photos of each fruit from above using vision technology. At that moment, the shape, thickness, length, and weight are recorded. This information is forwarded by the software to one of the seven robots hanging in a row above the conveyor belt. The gripper arms of these robots swiftly pick up each cucumber with their suction cups and stack them in crates next to the conveyor belt. The operator can set the desired crate and sorting via the machine’s dashboard. flexible conveyor system

“With this system, we can easily switch between crates, which is beneficial as we serve many different customers. In the morning, we often use six or seven types of packaging,” says Kees Vahl. He knows it is efficient to process three sorts simultaneously. “If you set only one at a time, the robots stand idle too often.” The speed at which the robot arms move is astonishing. Picking and packing one fruit takes a maximum of one second. The sorting line can process twenty thousand cucumbers per hour and 140,000 per day when running at full capacity.

The choice for automation in greenhouse horticulture is largely about labor savings. As Vahl indicated: labor is becoming increasingly expensive, but reducing monotonous work is also a motivation for him. “This is the future. I prefer to deploy my people elsewhere rather than for packing. When the line runs optimally, we only need six people: two for feeding, two for manual packing, someone to prepare crates and boxes, and a process operator. Previously, fifteen people were sorting and packing.”

For benefits and quick entry click here

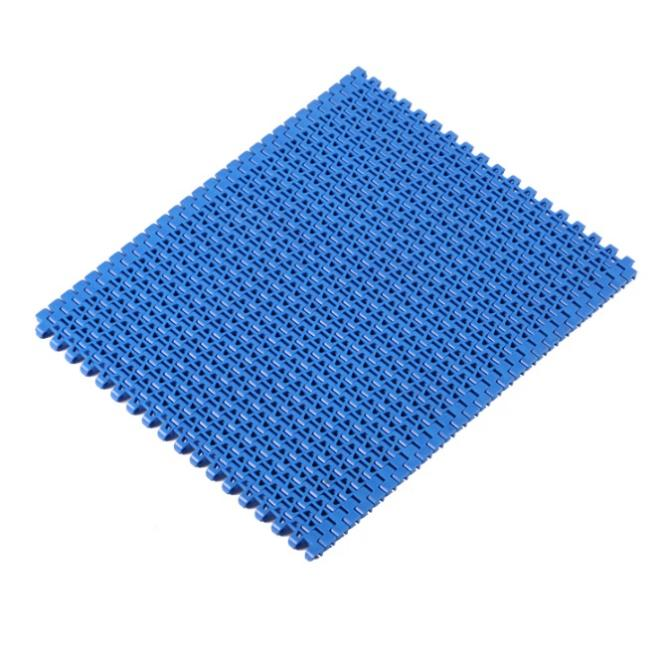

Lf880tab Series Plastic Chain "* " indicates required fields