By Bob Beacham, Tom Scalisi

Updated on May 9, 2024 12:10 PM EDT Right Angle Pin Header

We may earn revenue from the products available on this page and participate in affiliate programs. Learn More ›

The best crimping tools can help a variety of wiring projects go smoothly. That’s why we performed hours of hands-on testing with some of the top products on the market. From crimpers meant for installing nylon terminals on small cables and wires to those designed for heavy-duty battery lugs and aluminum terminals, we collected models to fit every need and then put them to the test.

Use this guide to understand the types available and the factors and features to keep in mind when shopping. We spent 8 hours testing all of the following models on six different sizes of wire with a variety of terminals to make the shopping process even easier.

We wanted to ensure that we were suggesting only the best crimping tools. To do so, we drew upon our experience in DIY and electrical work to pick out the most important features a wire crimper tool should offer.

Once we knew what to look for, we rounded up a selection of wire-crimping tools we felt would meet our needs and tested them. We used them to install terminals on a variety of wires ranging in thickness, also known as American Wire Gauge (AWG), or simply “gauge,” for the best crimping power.

These included 18-gauge, 12-gauge, 10-gauge, and 4-gauge wires to accommodate crimping capacity. We tested the ratcheting functions, assessed how easy the tools were to manipulate, and ultimately how well they secured the wires, then tested the finished connections with a multimeter. We then compared prices, features, and accessories to determine whether they offered enough value.

The following wire-crimper tools passed muster in our tests and were given awards based on their strengths and crimping force.

With precision and durability in mind, we researched a wide variety of wire-crimping tools before landing on these products. We then tested these top-rated tools to ensure we had the best products on the list.

Anyone hunting for a do-all crimping solution will want to check out this Iwiss tool kit. It comes with a ratcheting crimper, six sets of jaws for a variety of terminal connections and wire gauges, and a set of wire strippers with cutters, allowing users to tackle just about anything.

The Iwiss crimping tools in this set feature a crimper with a ratcheting mechanism that creates double crimps in certain types of terminals, ranging from 22 AWG to 2 AWG. Once the crimpers finish the double crimp, the quick-release handle opens automatically. Also, swapping the wire-crimper jaws is simple, requiring the user to simply press the spring-loaded pins to swap them out.

The Iwiss wire-crimping tool was our favorite during the test. It provided plenty of leverage to make crimping down on tough terminals easy. We also liked the quick-release jaws, as they easily slide in and out but stay securely in place. The grips were also comfortable in hand and nonslip, which can be a big benefit when trying to hold a wire into a connection while crimping.

It also comes with its own case to keep things organized, which is great, as it’s too big for a tool box. (It’s 11 inches long, 8 inches wide, and 2.5 inches thick.) Otherwise, it was durable, comfortable, and easy to use. We really enjoyed working with it, which easily made it our favorite pick.

Read our full review:Iwiss Kit-0535 Ratcheting Crimper Tool Review

Get the Iwiss crimping tool set at Amazon.

This wire-crimping tool from Wirefy has been specifically designed for rapid productivity when working with common nylon electrical terminals. The color-coded die allows for quick positioning of the crimp, and double jaws create a high-strength connection. Light pressure holds the terminal in place without the operator needing to maintain grip. A star wheel sets precise crimping pressure, while the ratchet action applies double crimps quickly and with repeatable precision. The finished crimp is then auto-released once it’s double-crimped.

The Wirefy crimping tool handles sizes from 22 AWG to 10 AWG. Well-cushioned, nonslip handles add comfort through long work periods. The tool also features a compact profile of 11.42 inches long by 4.69 inches wide, so users can easily store it in a tool belt or box.

Our tests showed us that the Wirefy crimp tool has a lot going for it. We liked its relatively compact size, and despite a shorter grip than some of the competitors, it was easy to apply pressure and crimp terminals. The grip was also fairly comfortable, and size identification (it’s color-coded) was a breeze. It also has one of the smoothest ratcheting motions in the test.

We’re not huge fans of the jaws being made of multiple plates, as they’re far more likely to bend than solid jaws, but it did produce solid connections regardless.

Get the Wirefy wire-crimping tool at Amazon or Wirefy.

Folks looking to crimp on a budget will appreciate the ease of use, repeatable performance, and value of this Titan wire-crimping tool. It’s designed to handle the common insulated nylon terminal type with cable diameters from 22 AWG up to 10 AWG. The double-crimp die provides extra cable security. Jaws are color-coded for rapid identification and high productivity.

The ratcheting action provides control when tightening and can generate plenty of power, yet the action is light so hands won’t tire quickly. That’s because the ergonomic handles incorporate a quick-release lever for those occasional jams. Also, one of the handles features a quick-release mechanism that activates after double-crimping. The only drawback of this wire crimper is the jaws are made of individual plates rather than being solid jaws, which means they’re more likely to bend or deform.

For the money, we really like Titan’s crimping tool. The ratcheting action is smooth; the quickly-release lever is easy to operate; and it made secure connections. The action was light enough, too, that we were able to make multiple crimps in a row without fatiguing. Also, we found the quick-release lever to be easy to use, which is a plus when the terminal needs to be reset or realigned.

Get the Titan wire-crimping tool at Amazonor Titan.

Modern automotive circuitry allows for little intervention by mechanics or engineers—mostly it’s a question of identifying the fault and replacing the board. However, battery terminals still get damaged or frayed. The TemCo hammer crimper mounts to a workbench and provides an easy-to-use, highly durable solution and a straightforward, cost-effective method for low-volume situations.

There’s no need to worry about dies fitting incorrectly, since terminals simply rest in the V-shaped jaw. The crimping ram is then struck with a hammer or tightened in a bench vise. The ram is designed to accommodate wire sizes from 8 AWG up to 4/0 AWG, making the TemCo hammer lug crimper suitable for attaching heavy-duty terminals to welding equipment cables, but not small wires and terminals.

The TemCo Hammer Lug Crimping Tool was truly one of our favorites. We used it for battery lugs and heavy-gauge wire. Although it’s specifically designed for use with larger wires, we tested it with terminals much smaller than suggested, and it actually did great. It was the fastest method for securing a terminal in the test, but it does need a solid work surface to operate, so it’s definitely better for a shop than a tool belt. However, it made excellent crimp connections, and it’s also fun to use as a battery cable crimper.

Get the TemCo crimping tool at Amazon or TemCo Industrial.

When it comes to installing wire crimps, it doesn’t get much easier than a hydraulic model like this one from TemCo. This hydraulic cable lug crimper installs a range of terminal types on wires ranging from 12 AWG all the way to 2/0 AWG. This kit even comes with dies in half sizes for terminals that are difficult to fit.

The TemCo tool kit can handle building wires, battery and welding cables, and smaller wires. The hydraulic piston easily closes the dies, while the spring-loaded handle returns the handle to its open position naturally. And because it’s so easy to squeeze with one hand, the user is able to hold the wire steadily in the free hand for perfectly aligned terminal connections. At 9 pounds, this crimper is heavier than most other models.

We had to break out some serious cable to test the TemCo TH0006 hydraulic cable lug crimper. We found that its dies were very easy to change and that it had plenty of power for crimping down on heavy-duty terminals. It was a little heavy in hand, which did make wire and terminal alignment a little awkward, but the resulting connections were extremely strong. We even used it for lighter wires, like 10 wire gauge, and found the same results. Also, it comes with 18 different dies, and the dies themselves are very easy to swap.

Get the TemCo TH0006 at Amazon or TemCo Industrial.

Folks looking for a light-duty crimper they can easily keep in their tool belt while on the job will want to consider Irwin’s wire-stripping tool. This good crimping tool has several built-in capabilities, including stripping wires between 22 AWG and 10 AWG, wire cutters, pliers, bolt cutters, and crimping tools for terminals between 22 AWG and 10 AWG.

This is a light-duty tool, as it performs single indent, single-crimp connections. It also has thick, textured grips for nonslip control and cushioning.

We used the Irwin crimping pliers for the entire test. We cut and stripped all of our wires with it, allowing us to assess its multifunction capabilities. It cut well (even our thick 4-gauge wire), and stripping was sufficient. It also made solid connections, but we did have to make two crimps for the best connection. However, for a tool weighing under a quarter of a pound, it had no problem crimping down on the terminals despite not having a ratcheting function. We also like the control that the nonslip grips offer.

Get the Irwin crimping tool at Amazon, Ace Hardware, or Acme Tools.

Thick cables and heavy-duty lugs require more leverage and force. The Iwiss single cable lug crimping tool has what it takes, with its extended handles for leverage and nonslip grips for a sure hold while bearing down. It also comes with rotating dies for six different wire gauges: 8, 6, 4, 2, 1, and 1/0. This heavy-duty lug crimper from Iwiss is made from high-quality steel and is compatible with copper and aluminum non-insulated lugs as well as non-welding, standard electrical wire connectors.

It isn’t often that we’d use a cable crimper like the Iwiss single cable lug crimping tool, but we found that it made crimping heavy lugs a breeze. It has long handles that apply plenty of force to the jaws, ensuring strong connections. And despite the weight and front heaviness, the textured grips make controlling the crimper easy.

The dies are also easy to swap, as the user simply presses down on the retaining button, spins the wheel to the correct size, and releases the button. The one issue we had with this cable crimping tool was identifying the different die sizes in anything less than the midday sun—the labels are hard to see.

Get the Iwiss HX-50BI crimping tool at Amazon.

The Klein Tools 3005CR is another reliable crimping option that shoppers will want to consider. This tool features steel construction, solid double-crimp jaws, and a ratcheting function that allows users to hold the terminal in place, apply pressure, readjust their hands, and continue crimping. It has three terminal bays, including 22-16 AWG, 16-14 AWG, and 12-10 AWG, which are easy to identify with the color-coded jaws.

This is a well-built tool; it felt like one of the sturdiest in the bunch with its solid double-crimp jaws that are unlikely to deform. However, we felt that the ratcheting function wasn’t as smooth as it could be, especially compared with other models. Also, toward the end of the crimping motion, we felt it needed more pressure to trigger the quick release than the other models. However, the grips were extremely comfortable (the best in the test by far), and the heavy-duty construction felt like it would last for years.

Get the Klein 3005CR crimping tool at Amazon, The Home Depot, or Acme Tools.

The mechanical actions mentioned should play a role in the choice, but several other factors must be taken into account as well. Read on for details about materials, applications, and more to help with choosing the best crimping tool for wiring projects.

Many electrical connections rely on a terminal (a bolt-down or push-fit connector) with an open end crimped onto the bare end of a wire or cable. The terminals, often simply called crimps, are made of metal and are usually shrouded in PVC or nylon. A crimping tool squeezes the crimp shut, forming a secure join between the terminal and cable to protect any electrical connection. Most crimping tools are squeezed like a pair of pliers, though they are larger and their mechanisms and jaws vary considerably.

Cable (or wire) thickness is usually given in AWG or gauge. The crimp needs to be a corresponding size for the connection to work properly. At its thinnest, gauge can be around 0.01 inch in diameter, though 18 gauge (0.04 inch) is the thinnest in common use. By contrast, the maximum AWG, 4/0, is almost 0.5 inches across. Larger cable diameters are generally given as MCM, which is an abbreviation for “thousands of circular mils,” and can exceed 1.5 inches.

As each cable size can be connected to a variety of different terminals, no single crimping tool can handle every job. There are three basic types of crimping tools: handheld, hydraulic, and hammer.

Handheld crimping tools are the most common electrician’s tools. They’re usually very affordable and offer considerable versatility. These crimpers range in size; some sit easily in the palm of a hand and are designed for high-precision work (like small terminals and wire splices), and there are models more than a foot long that offer the leverage required for heavy-duty crimping.

Although many use a simple squeezing action like ordinary pliers, a ratchet is often employed to provide consistent, repeatable pressure application. Jaws vary to accommodate different types and sizes of terminals. To offer increased range, some handheld crimping tools have interchangeable jaw sets. They may also incorporate wire strippers and/or small bolt cutters, making the tool multipurpose.

While mechanized hydraulic wire-crimping tools are available for production lines, most of this type are still manually operated. They use an oil-filled cylinder actuated by a lever, thus dramatically increasing output pressure. Hydraulic crimpers are usually rated by the force they can apply. This is measured in tons per square inch (anywhere from 8 to 16), underlining the terrific power they can generate.

Although frequently used in heavy-duty applications, a hydraulic crimper can handle medium-size terminals thanks to interchangeable crimping dies; these steel jaws are specially shaped to close the crimp firmly. The tools are usually supplied with a selection of these—a typical example might contain from 8 AWG (0.12 inch) to 0-250 MCM (0.68 inch).

Hydraulic crimping tools are easy to use but do require occasional maintenance. If air gets into the cylinder, for instance, it will reduce performance, so purging may be necessary. Oil seals also need to be changed periodically.

A hammer crimping tool is a basic, low-cost device, often making it best for those who only need a crimper occasionally. However, it is also a robust and compact tool that can put up with tough environments and is often found in automotive shops and wherever else heavy-duty crimping is required.

A hammer crimper doesn’t use dies but instead consists of a height-adjustable, wedge-shaped ram on a sliding carriage with a V-shaped groove at the base. The crimp and cable to be connected are simply placed in this groove.

As the name of this crimper suggests, closing the terminal is a matter of hitting the wedge with a hammer. A 2- to 4-pound sledgehammer is recommended, though any heavy hammer will do. A bench vise could also be used to press the ram onto the crimp.

Crimping tools of all types are invariably made of steel. Carbon steel is often cited as offering high durability, but this can be a bit misleading. All steel is a mixture of iron and carbon, so the term “carbon steel” can apply to any of these metals.

For increased toughness, look for high-carbon steel (a small but important difference) or hardened steel. The latter is especially appropriate in hydraulic and hammer crimping tools because of its resilience to high pressure and repeated impact.

Handheld crimping tools usually have plastic or rubber grips on the handles for added comfort. On cheap crimping tools, these can be quite thin and prone to splitting. Better-quality models frequently have thicker padding and better ergonomics, offering a more secure grip.

DIY and hobby users will often try to find a single tool for multiple applications. It’s perfectly understandable as it helps reduce expense, but improper fit or pressure often results in faults. There really are no “jack-of-all-trades” solutions when it comes to crimping tools, so it’s often best to be specific.

This is particularly true when dealing with specialist connectors. Fortunately, it’s not difficult to find a variety of alternatives for every application that include choices ranging from decent budget-friendly tools to professional tools. Contractors often buy several different crimping tools, finding that the efficiency and reliability of having the right tool for the job more than makes up for the extra expense.

Crimping tool product descriptions usually offer good guidance, but those who are unsure of which one they need will want to do further research. Using the wrong type can result in poor connections that eventually lead to a breakdown.

In factories and other high-productivity situations, automated machinery is used. Such tooling isn’t typically necessary in most general electrical projects, but volume of operation (or frequency of use) is still an important consideration.

For example, a hammer crimping tool is often found in auto shops for refitting battery cables. If it’s only needed as occasionally as once a month, an inexpensive tool may offer adequate performance and good value. If the same task had to be undertaken several times a day, a hydraulic crimping tool would make more sense. These cost more, but they’re faster and require less effort.

Similarly, a basic handheld crimping tool might suffice for folks who tinker with electrical devices as a hobby. A pro who does the same types of repairs on a daily basis would choose a ratcheting model so every crimp had the same pressure applied, every time. These also release automatically, increasing productivity.

Hydraulic and hammer crimpers are heavy-duty tools that can handle the largest of wire gauges. The former is limited by the die sizes available, and the latter by how much physical force can be applied. Crimp profile—the shape of the crimp before it’s compressed, which varies according to connector type—is unimportant with these tools because a limited variety is used.

With more general electrical projects, such as repairing household appliances or electronics, there are a number of different profiles. These include hex, indented, circular, B crimp, and others. The profile defines how the crimp closes around the cable, so choosing the right type of jaw is vital in providing safe and secure electrical connections.

Most handheld crimping tools will offer a range of cable gauges and should make clear the type of profile they provide. However, that’s not always the case, so it’s always a good idea to check the specification provided by the manufacturer.

Electrical crimp connectors come in dozens of different materials and styles: nylon, PVC, non-insulated, insulated, heat shrinkable, ring, spade, Faston, Lucar, Shur-Plug—the list is extensive.

Many of these descriptions have little impact on the type of crimping tool used, as they define the type of connection being made between two components. However, some types of crimping tools work better with nylon wire connectors than PVC, for example, making it important to understand the specification of the connector to select a suitable crimper. Often the manufacturer makes this easy, not just by giving clear definitions but also by color-coding the jaws for rapid visual identification.

Although it’s a good policy to buy a crimping tool that’s as closely matched as possible to the specification of the cable size and crimps being used, these tools are not without versatility. Even basic models will handle a variety of cable and connector diameters. Better-quality tools may offer replaceable jaw sets, which allow the user to handle three or four times as many sizes and potentially different types of connectors as well.

Wire stripping is a necessary part of any crimping operation, and some tools incorporate blades for this purpose. Cutters for trimming cable to length may also be included. Crimping tool kits may extend this further with the addition of cable testers or the terminals themselves.

Those new to crimping tools may still want more info on how to shop for and use them. Check out the answers to commonly asked questions below.

Crimping securely attaches electrical connectors to the relevant cable. Types and sizes can vary enormously, from those on computer circuit boards to mains (the high-voltage cables that bring power to your home).

It’s not a matter of better; it’s about doing what’s appropriate for the project. Soldering is largely used for attaching wires permanently, whereas crimping is common for connections that can be disassembled. Learning how to crimp wires as well as solder is important for well-rounded DIYers and technicians.

The most important considerations are ensuring the tool can handle the type of terminal you need to attach as well as the appropriate wire sizes.

We’re committed to testing and reviewing products so you can make an informed decision. Advertising does not influence our product reviews and it never will. We always focus our coverage on standout products and never hesitate to mention their flaws and quirks. By using our affiliate links, you’re supporting our work and helping us continue to provide expert analysis. Find out more about our product evaluation process.

By Glenda Taylor, Mark Wolfe

By Andreana Lefton, Mark Wolfe, Tiffany Lewis

By Glenda Taylor, Tom Scalisi

By Tony Carrick, Glenda Taylor

By Glenda Taylor, Tom Scalisi

By Timothy Dale, Tom Scalisi

By Debbie Wolfe, Tony Carrick

By Nina Malkin, Katie Nolan

By Larry Bilotti, Margaret Foley

Subscribe to our newsletters for the best tips, tricks, and ideas to transform your home and yard.

By signing up you agree to our Terms of Service and Privacy Policy.

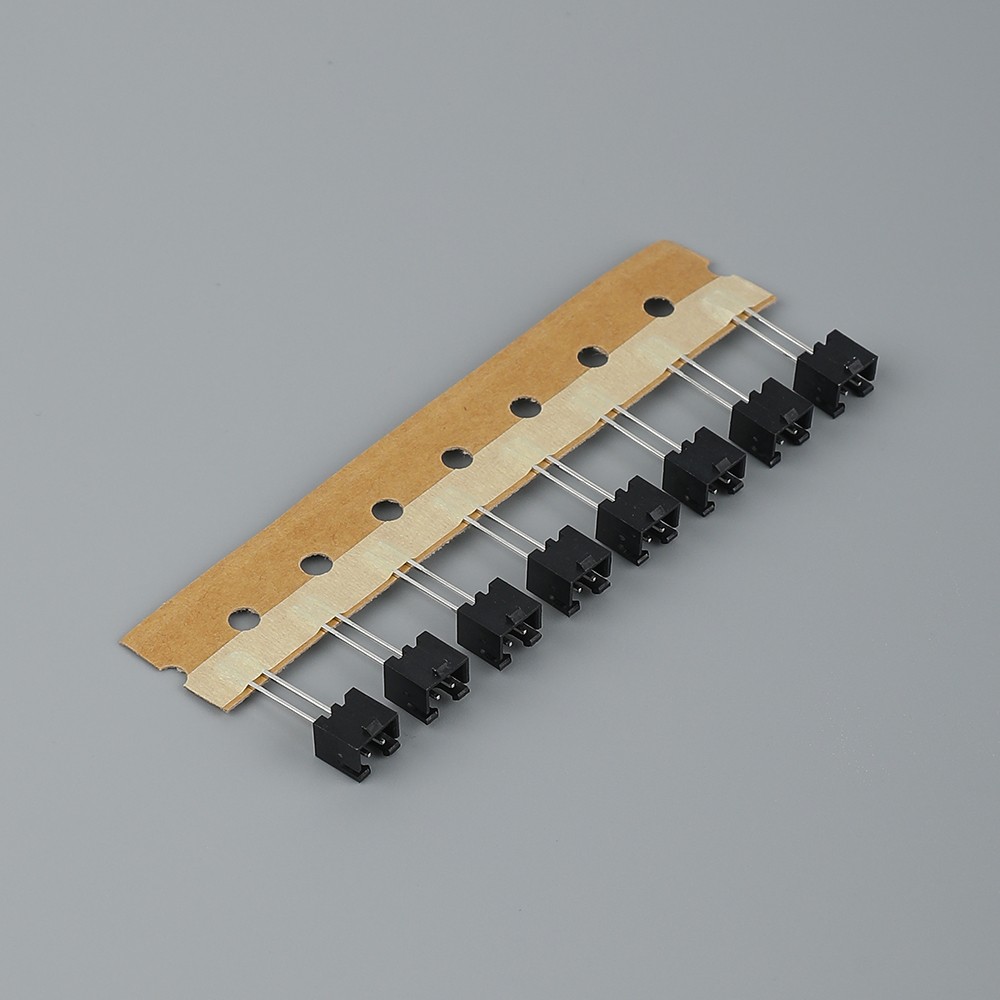

Screw Terminal Wire Connectors Articles may contain affiliate links which enable us to share in the revenue of any purchases made. Registration on or use of this site constitutes acceptance of our Terms of Service.