CML Biotech Ltd.’s business case presented by Husky Technologies™

LIVE WEBINAR / 28th of February 2024 at 2:00 pm IST Mould Oem Factory

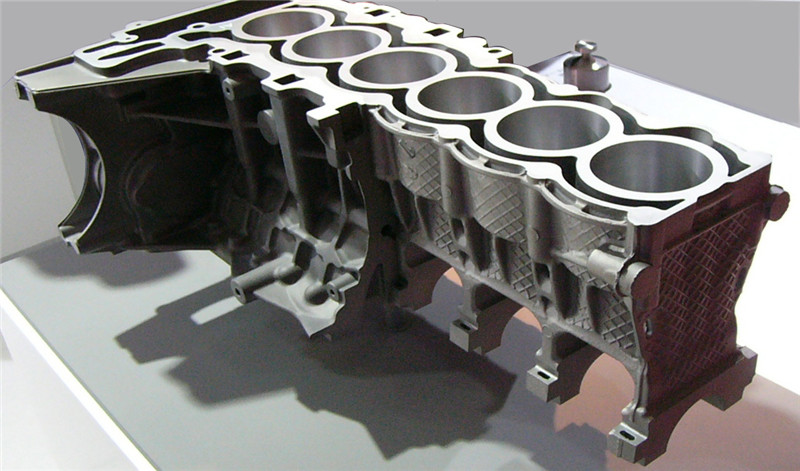

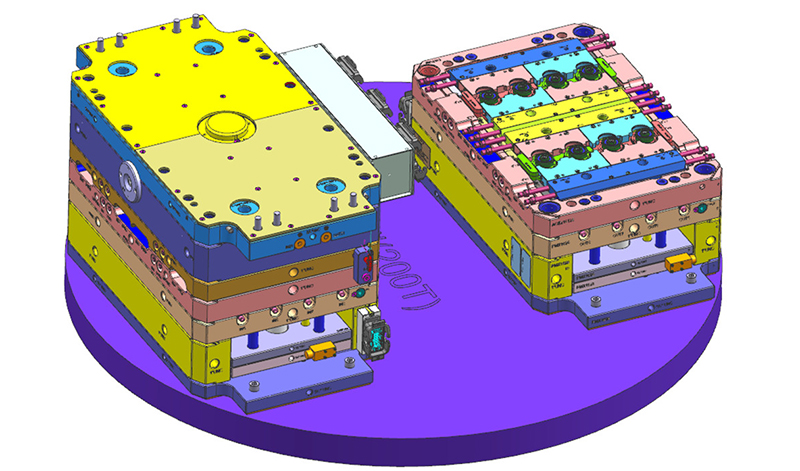

As the demand for injection-molded medical devices surges, manufacturers must navigate a dynamic market that now demands tighter tolerances, increased design flexibility, higher cavitation, and faster time-to-market. Traditional injection molding technologies, however, often fall short, forcing compromises in part design. To overcome this, leading manufacturers are turning to fully integrated injection molding solutions that operate as unified systems, eliminating boundaries, waste, and variability. Join our webinar on February 28th at 2:00 pm IST for a comprehensive look at the evolution of injection molding systems, and how an integrated medical system can optimize your plastic part design, enabling you to get products to market faster and cheaper.

●Trends, opportunities, and application requirements in the blood collection tube market ●The limitations of traditional injection molding for medical applications ●The advantages of fully integrated injection molding solutions for medical parts ●The benefits of Husky’s ICHOR™ system, the only fully integrated medical system ●How one of India's largest blood collection tube manufacturers used ICHOR™ to enhance part quality, minimize weight variations, and optimize cycle times ●And much more!

This webinar will offer insight and information for those who want to understand

the medical parts manufacturing market.

Hiren Khatri is an industry veteran with over 20 years in the injection molding industry. In these years, Hiren has held several keys roles at Husky, including Service Engineer, Hot runner and Controller Sales, Specialty Closures & Medical Project Sales, Rigid Packaging Beverage Project Sales. Before his current assignment, Hiren was leading Medical and Specialty Closure for Husky and Schoettli’s breakthrough Systems technology. Based at Schoettli India’s Branch in Mumbai as Key Account Manager of Medical System, Hiren is actively involved in all the major SAARC region Medical System projects of the company. Hiren is relentlessly promoting a unique integrated system approach to medical equipment injection molding, which removes artificial boundaries and variability that could exist when assembling components from different suppliers. This integrated system approach enables reducing risk and improving overall manufacturing performance, making Husky and Schoettli the ideal supplier for meeting today’s medical injection molding manufacturing market needs and expectations.

Connect with Hiren to find out more about our Medical Molds and Systems.

Injection Mold LIVE WEBINAR BY HUSKY TEAM