The Slipstick conveyor’s single-drive mechanism provides horizontal differential motion that glides product down the pan, eliminating the breakage of fragile foods such as chips, cookies or cereal. Source: Triple/S Dynamics.

The Heat and Control FastBack Revolution mid-gate system proportionally distributes product to multiple seasoning, weighing or packaging machines. Source: Heat and Control. Flat Conveyor Chain

The DoughVeyor lift conveyor for dough is based on a single-drive system and automatic infeed. Source: KOFAB.

Intralox ThermoDrive belts feature a tensionless drive system. Source: Intralox.

Strong and lightweight, the Omni-Flex 3 x 1 unit conveys pans, trays and large products in spiral cooling and freezing applications. Source: Ashworth.

Conveyors and the belts that run on them, whether they are polymer, metal, hybrid or fiber, connect raw material reception, processing, packaging, palletizing, accumulation, final delivery and a myriad of other things.

One of the great early users of conveying was Henry Ford with his assembly line approach to making cars. The conveyor industry has advanced a long way since then. Today, many choices are available for food and beverage processing and packaging applications. They’re all different, and they all have their own unique advantages.

According to Ken Ruehrdanz, manager of the systems distribution market for Dematic, a modular architecture is the way of the future. “More and more users will likely implement conveyor systems that are engineered as standard modules, allowing faster and easier layout changes,” he says. “Modular architecture features common components throughout, thereby allowing universal connectivity and requiring fewer spare parts.”

The Dematic plug and play steerable wheel sorter is a modular device that mounts inside the universal side frame of the Dematic modular conveyor system. If divert locations change, the sorter can be easily relocated along the conveyor path by removing the rollers in the conveyor at the new location. The module is then bolted onto the side frame of the conveyor, while the controls are configured and connected.

An important feature of automated conveyor systems, accumulation or “buffering,” consists of either extra lanes or vertical spiral belts that allow packages to collect, if there is a hiccup in production from the packaging machine or a downstream jam-up. With this feature, operators can quickly clear the problem instead of shutting down the line and starting it again.

Accumulation equipment can be first-in-first-out (FIFO) or first-in-last-out (FILO). FIFO is useful where more sensitive products need to be coded and tracked on a case-by-case basis before final shipment, while FILO is suitable for applications that do not require close tracking. Many types of accumulation equipment deliver products randomly or somewhere in between FIFO and FILO.

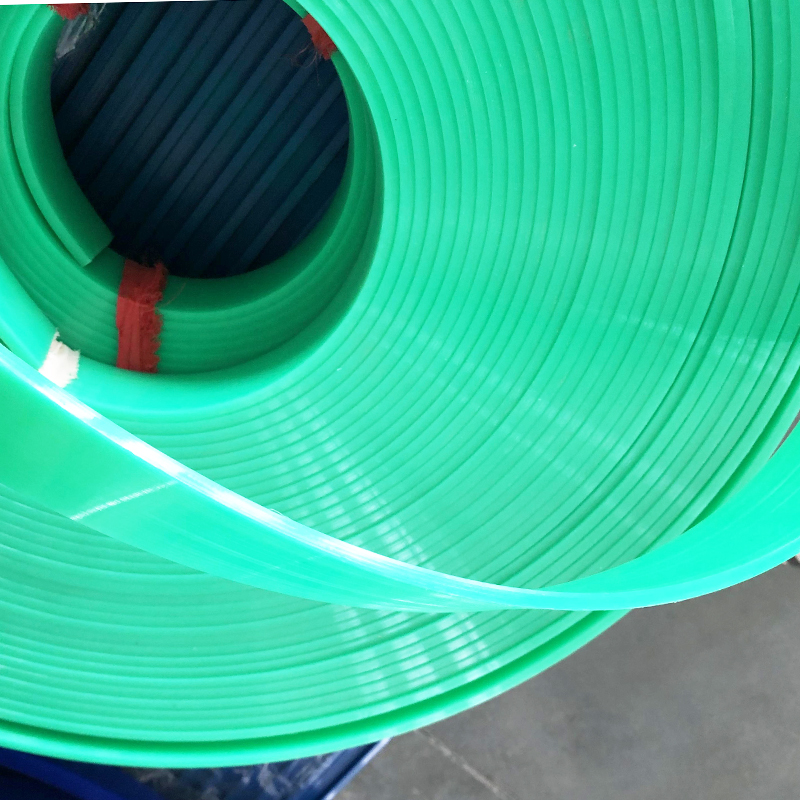

Many types of conveyor belts are available. Those with articulated polymer designs are among the most cost effective. But the industry-wide push over recent years toward greater levels of food safety, demanded by FSMA and GFSI, have also created a trend to metal, which is easy to wash down and sanitize.

Ken King, Ashworth Brothers commercial support manager, notes tight economic times are causing food manufacturers to invest in refurbishing or rebuilding existing conveyors, instead of investing in new ones to improve product yield, quality and shelf life. “When it becomes necessary to replace a conveyor belt, manufacturers look for one that is reliable, easy to clean and sanitize, and durable enough to convey increased product loads,” he notes. “They’re also looking for wider belts, speeds exceeding 100fpm and more robust support structures to carry greater product loads.” But there’s a trade-off, too, because heavier loads, faster speeds and greater belt tension add up to faster wear and reduced belt life expectancy.

The Ashworth Omni-Pro spiral product belt line includes 360° buttonless welds that are constructed without surface imperfections and crevices to improve hygiene and eliminate the possibility of microbial entrapment. The Ashworth Advantage hybrid plastic spiral freezer belt “provides superior airflow and enhanced product release characteristics that minimize product damage and reduce energy costs,” says King.

For example, a commercial bakery based in the Northeast had been using metal belting in its spiral freezer for at least two decades to convey its line of frozen dough products. The conveyor system was separated into three components to incorporate a knife-edge transfer and accommodate the weight of the metal belt. With three different conveyor belts came three times the chance of failure and downtime.

When the time came for a replacement, the bakery decided it wanted a cleanable, easy-to-repair belt that was lightweight and resistant to breakdowns. The bakery chose the Ashworth Advantage 120 spiral belt with a metal/plastic hybrid design, because it incorporates the benefits of traditional plastic—lightweight and quick to repair—combined with the benefits of metal: strength, durability and easy cleanability. The Advantage 120 belt provides the transfer applications the bakery needs. Plus, the three conveyor components have been combined into one smooth-running system.

Ashworth recently released the Omni-Flex 3 x 1 conveyor belt with three- by one-inch openings that effectively reduce the weight of the belt. This makes the belt a more economical option for conveying pans, trays and larger products in spiral cooling, freezing and general conveyance applications.

Killian Lapeyre, Intralox global snack team leader, agrees that sanitation and hygienic design, along with good paybacks, are creating greater interest in new conveying solutions. “On all fronts, with the higher cost of downtime, reliability and faster troubleshooting are becoming critical.”

The Intralox ThermoDrive belt offers zero-pretension operation, enabled by limiter technology, to ensure loose running of the entire conveyor system. This results in extended belt life, minimized costs, reduced downtime, improved belt-edge integrity and increased efficiency.

In addition to food safety, food security is a major concern for processors. For example, Salumificio Fratelli Beretta was having problems with its metal spiral conveyor for drying salami at one of its plants in Italy. Most of the issues had to do with metal from worn parts that required an inordinate amount of cleaning time and cost. Intralox solved the issue with a modular plastic DirectDrive S2800 belt, which provides a greater uniform open area for cooling and increased airflow, and creates no metal debris.

When processors analyze cost of ownership, they should look at the belt separately from the conveyor, observes King. “All too often, the conveyor belt is viewed as an accessory and not an engineered product. This viewpoint can potentially have a profound impact on conveyor performance and operating cost.” When considering the use of either plastic or metal, he says processors should consider a number of factors.

Typically, metal belts can be cleaned with a mild detergent, while plastic spiral belts generally require expensive, highly chlorinated cleaners and sanitizing agents—especially in meat, poultry and cheese processing facilities. But, over time, chlorinated cleaners and sanitizing agents can impact the structural strength of a conveyor.

Most metal belts have a USDA-approved, slotted hinge design that minimizes product buildup and provides an avenue for water to flush out food debris, reducing cleaning time.

However, hinge areas in plastic modular belts tend to retain product in and around the connector rod, restricting the ability for water to get through, adding to cleaning time and cost. Spiral systems that use plastic belts also require more rails to support the product and belt load. These in turn require additional time to sanitize.

Temperature is another factor. Plastic modular belts are more susceptible to stretch and contract due to sudden changes in temperatures, such as those found in the sanitation process. If the temperature is not managed properly by the sanitation and maintenance staff, the belts and modules will be damaged. Although plastic modular belts take less time to repair and re-install than their metal counterparts, they require more frequent maintenance, meaning long-term costs can be higher.

While thermoplastic belts are easy to clean because of their closed, flat surface, they often must be cleaned via COP tank soaks. Guy Mitchell, an administrator at Wire Belt, points out metal belt users have the advantage of using the conveyor’s built-in CIP system of strategically placed nozzles operated by the push of a button. “The bottom line is processors need solutions and services that reduce downtime, minimize total cost of ownership and increase efficiencies in the process,” explains Mitchell.

The Wire Belt Flat-Flex belt has an open (up to 86 percent) mesh surface matrix, which provides flow-through for air, liquids, powders, slurries and other media used in coating, dusting and washing. It also provides support for the product being conveyed.

A few years ago, Wire Belt introduced a version of the Flat-Flex belt that has a closed- rather than open-loop edge. This edge design helps the belt last longer, because it minimizes conveyor-to-conveyor catches and snags. It also minimizes the possibility of an operator getting his or her fingers caught in the belt.

Heat and Control, Inc.’s FastBack horizontal conveyors use a slow-forward, fast-back motion that slides product instead of bouncing it. This reduces product breakage and stress fractures, as well as the loss and buildup of seasonings and coatings in the pan—problems commonly associated with vibratory conveyors. The conveyors operate at a 70dB noise level with minimal transmitted vibration, enabling the use of lighter, less expensive support platforms.

Offering proportional product distribution, the Heat and Control Revolution gate system also eliminates the product breakage and pinch-point hazards of slide gates. A smaller Revolution mid-gate distribution system is now available for medium-capacity processors; multiple units can be installed on the same FastBack conveyor pan to accommodate tight weigher spacing.

The FastBack WeighBack conveyor provides continuous load cell weight measurement and is more sanitary than conventional weigh belts. Other FastBack conveyors are engineered for uphill conveying, inline storage and product blending.

In the early 1970s, Triple/S Dynamics pioneered the use of horizontal motion conveying. According to Sanitary Equipment Product Manager Tim Talberg, Triple/S Slipstick conveyors are mainly used for conveying bulk materials, with little or no product breakage, dust generation or segregation. The units feature a one-piece, seamless pan design for ease of cleaning; the pans are available in lengths up to 200 ft. or more to minimize the number of drivers required.

Triple/S Tex-Flex conveyors for screening bulk materials are free of external bearings, require minimal lubrication and maintenance, and consume less than 1 hp of energy.

The KOFAB Curveyor features tight transfers and small-diameter infeed and discharge rollers that allow small products to be transferred without large gaps or product damage. The conveyor has a 30° to 180° turning range and can be configured to turn left and right. Its all-stainless steel construction includes continuous welds, USDA-/FDA-approved belts, nose bar assemblies and a belt that can be changed in minutes.

The KOFAB DoughVeyor positive drive dough-lift conveyor is based on a single-drive system and automatic infeed section. It includes a self-track belt, pneumatic tensioning and stainless steel drive pulleys.

“Back in the old days, it was probably acceptable to build a piece of equipment that achieved one goal,” says Bill Schiltz, KOFAB director of sales and marketing. “Today, it’s important to focus on sanitary design, operational efficiencies and functional design.”

Killian Lapeyre, Intralox, 800-535-8848, killian.lapeyre@intralox.com, www.intralox.com

Ken King, Ashworth Brothers, 540-665-1309, kking@ashworth.com, www.ashworth.com

Guy Mitchell, Wire Belt Company of America, 603-518-2308, gmitchell@wirebelt.com, www.wirebelt.com

Tim Talberg, Triple/S Dynamics, 763-201-1296, ttalberg@sssdynamics.com, www.sssdynamics.com

Bill Klein, Heat and Control, Inc., 800-227-5980, billk@heatandcontrol.com, www.heatandcontrol.com

Kevin Mauger, NCC Automation Systems, kmauger@nccas.com, www.nccas.com

Bill Schiltz, KOFAB, 515-295-7265, wjschiltz@kofab.com, www.kofab.com

Ken Ruehrdanz, Dematic, 616-913-5931, kenneth.ruehrdanz@dematic.com, www.dematic.com

You must have JavaScript enabled to enjoy a limited number of articles over the next 30 days.

Sponsored Content is a special paid section where industry companies provide high quality, objective, non-commercial content around topics of interest to the Food Engineering audience. All Sponsored Content is supplied by the advertising company and any opinions expressed in this article are those of the author and not necessarily reflect the views of Food Engineering or its parent company, BNP Media. Interested in participating in our Sponsored Content section? Contact your local rep!

During this webinar, led by a panel of leading experts in this technology, we’ll immerse ourselves in the cutting-edge of Membrane Bioreactor (MBR) technologies.

For webinar sponsorship information, visit www.bnpevents.com/webinars or email webinars@bnpmedia.com.

Combining scientific depth with practical usefulness, this book serves as a tool for graduate students as well as practicing food engineers, technologists and researchers looking for the latest information on transformation and preservation processes as well as process control and plant hygiene topics.

Copyright ©2024. All Rights Reserved BNP Media.

Square Tube End Caps Design, CMS, Hosting & Web Development :: ePublishing