The energy industry is continuously innovating to provide new productivity enhancement solutions that are cost-effective and increasingly focused on ESG. StimStixx Technologies offers a revolutionary stimulation technology to stimulate wells that is deployable on wireline and slickline.

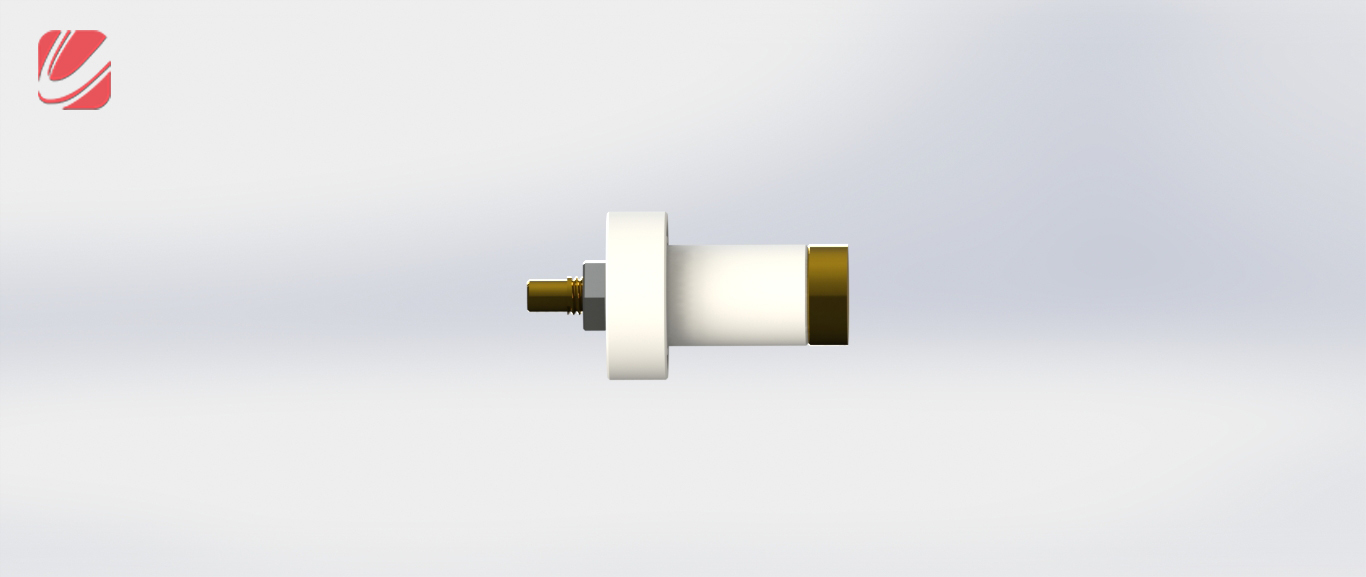

For operators to increase production there are two general approaches – initiate capital-intensive drilling campaigns to bring new wells online or increase production and extend the life of existing wells. The capital cost and inherent risk involved with drilling new wells can be cost prohibitive when compared to increasing productivity of existing wells. To address the need for a cost effective and targeted acid treatment, StimStixx Technologies completed their first proof of concept wells in 2017. Since then, the company has grown and currently has ongoing onshore and offshore projects in over 15 countries worldwide. This downhole tool gives operators the option of deploying acid on e-line and slickline in a cost effective and safe manner while also reducing the carbon footprint when compared to conventional acidizing methods. Cable Termination Joint

The operating mechanism of the tool has some parallels to perforating guns but with some important distinctions. As with a perforating gun, an electrical signal is sent from surface to the tool downhole via wireline. Unlike the perforating gun, the StimStixx tools do not contain explosives. Hermetically sealed inside the tool is a dry chemical blend that undergoes a chemical reaction which is initiated by the electrical impulse. The products of the chemical reaction – either HCl or HCl/HF (Mud Acid) – are generated in a heated vapour state over a 15 – 30-minute period. This is the primary benefit of the tool – acid is generated directly in front of the zone interest in an uncontaminated form.

Another benefit is that by generating the acid downhole, this eliminates the acid from reacting with tubulars on the way down while avoiding any dilution or contamination associated with conventional pumping jobs. Additionally, by being in heated vapour state this improves the reactivity of the acid leading to higher rates of acid spending.

The tools are composed of 5 parts. The heart of the tool is the chemical carrier tube that contains the proprietary inert dry chemical blend which is hermetically sealed inside the carrier. Above the chemical carrier is a firing head that is connected to the CCL (Casing Collar Locator). The CCL is used to get pin-point accuracy on the tool placement to ensure the acid vapour is generated in front of the targeted interval.

Below the chemical carrier is a dispersion tube where the acid vapour exits the tool. The dispersion tube is typically placed in front of the targeted. At the bottom of the dispersion tube is a tapered bullnose that helps guide the tool when running in hole.

The tools come in a variety of sizes ranging from 2” up to 3 ½” OD. The smaller tools are ideal for through-tubing applications and the larger tools are used when the tubing is not present.

Operators typically select StimStixx for one of four primary reasons: to reduce stimulating costs, to stimulate in a safer manner, to benefit for the pinpoint accuracy, and to reduce the carbon footprint. The cost reduction is achieved by the reduction the amount of equipment, personnel associated with bullheading and coiled tubing acid treatments (acid haulers, pump trucks, stimulation barges, etc). Due to the lower volume of acid, there is no requirement for flow-back equipment as the acid is typically fully spent. For onshore applications, the rig-time is reduced on average of one to three days. The rig-up is quick and post treatment, the tool is simply out of the well and quickly disassembled.

The stimulation is inherently safer than conventional method since there is no handling of live acid at surface. This is of particular interest for operators that want to employ HF in their wells and the associated risks that go along pumping HF from surface.

The technology is particularly attractive when multiple intervals with different reservoir characteristics are present. For example, in wells that have both carbonate and sandstone intervals, a targeted approach can be applied where HCl tools are used for the carbonates and HCl/HF for the sandstone intervals. In cases where wireline data is available (e.g., lithology, PLT logs), the tool placement can be tailored to target these specific zones making for a more effective and efficient treatment.

The tools have proven to be highly effective in a wide range of applications including new and existing perforations, gravel packs, sliding sleeves and screens.

StimStixx Technologies continues to innovate and will be deploying new tools to the marketplace to further increase efficiencies.

Cable Coupler Joint To learn more about the full product line and how productivity can be enhanced on the existing wells, please visit www.stimstixx.com or follow the company on LinkedIn www.linkedin.com/stimstixxtechnologiesinc.