Researchers from Greece and France, in their latest article published in the journal Energies, have studied the influence of rotor bar shapes to increase the efficiency of a single-phase induction motor.

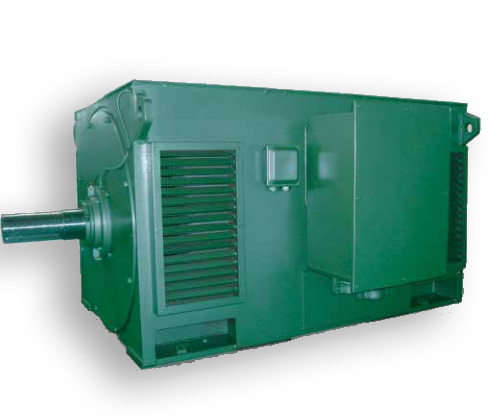

Study: Effect of Rotor Bars Shape on the Single-Phase Induction Motors Performance: An Analysis toward Their Efficiency Improvement . Image Credit: yura borson/Shutterstock.com YE2 Series

Worldwide, obligatory requirements for the effectiveness of line-operated electrical motors have been established. Compact single-phase induction motors (SPIMs) will not be spared in terms of effectiveness and efficiency, as new restrictions are set to be implemented no later than July 2023. As a result, the efficiency of capacitor-run SPIMs will be required to exceed (now) normal values and meet the standards of the IE3 (i.e., premium) performance class. Less consideration has been given to the influence of rotors bar form on SPIM performance and starting capabilities. This area was covered in this paper by investigating rotor squirrel-cage layouts with eight distinct bar forms.

International efficiency classes for four-pole IMs at 50 Hz. Image Credit: Chasiotis, I.D et al., Energies

Single-phase induction motors (SPIMs) account for a sizable portion of the worldwide electric machines industry due to their widespread use in a variety of products (e.g., cutting tools, pressurized cleaning technology, rotating belts, latest efficient washing machines, commercial grinders, food storage facilities, food mixers, microwave ovens, conditioning units, thermal circulation pumps, fans, centrifugal pumps, etc.). Their rated output power ranges from a few kilowatts to a few hundred kilowatts, and they are available in a variety of designs depending on the mechanism used to make them self-starting motors.

They are available in five varieties: (a) split-phase, (b) shaded poles, (c) capacitor-start/induction-run, (d) capacitor-start/capacitor-run, and (e) capacitor-run SPIMs. Because the transmitted single-phase current generates only a pulsing electromagnetic field, the beginning mechanism is required.

This motor's construction is quite identical to that of a three-phase squirrel-cage induction motor (IM). The fundamental distinction is in the configuration of the stator's primary and supplementary windings. These coils are 90 electrical degrees phase-shifted vertically. During both the initiating and operating operations of the motor, a fixed capacitor is linked in series with the secondary coil.

The stator and rotor core of the SPIM are composed of thin laminae of electrical metals. The squirrel-cage of the rotor is manufactured of a conducting alloy by die casting. Because of its inexpensive cost, aluminum alloy is more commonly used in the fabrication of tiny SPIMs, and it provides for greater freedom in the design of the bar.

Several configurations of semi-closed, closed, or open slots have been presented for the rotor bar design to determine which one advantages the motor's performance parameters. Based on the National Electrical Manufacturers Association's guidelines, the bar designs are categorized into four categories (design classes). Each of these results in a unique torque–slip profile for the motors and has a significant impact on the machine's operating efficiency and launching capabilities.

Impact of Crun and kbar on efficiency of SPIMs with rotor squirrel-cage bars of: (a) trapezoidal, (b) oval, (c) pent, (d) polygonical, (e) round, (f) drop, (g) rectangular, and (h) quadrangular shape. Image Credit: Chasiotis, I.D et al., Energies

To date, research studies have focused on the emergence of more precise magnetic and thermal models for better assessment of the motor's electromagnetic and thermal behavior, the optimized rotor squirrel cage configuration, the appropriate choice of the rotor bars/stator slots conjunction, and the establishment of innovative casting processes as well as novel materials for cores and squirrel cags.

Because the majority of the aforementioned solutions are not easily adaptable to large-scale production, it is critical to have design techniques that cause minor alterations to the pre-existing SPIMs manufacturing stage.

View (½) part and magnetic flux density distribution under nominal operation of the SPIM with Crun = 18 μF and rotor bars of: (a) trapezoidal, (b) oval, (c) pent, (d) polygonical, (e) round, (f) drop, (g) rectangular, and (h) quadrangular shape. Image Credit: Chasiotis, I.D et al., Energies

The influence of the rotor bar shape on the efficiency of the capacitor-run SPIM was examined and given in the study. The results showed that the design of the bar had a significant impact on the particular performance parameter. The gap between the lowest and maximal efficiency values of the best-performing SPIMs was 0.42 percent.

The discrepancy between the lowest and greatest efficiency values of the SPIMs with varying rotor bar shapes for a given capacitance ranged from 0.31 percent to 0.98 percent. It was pointed out that the bar shape had a significant impact on various operational features such as beginning current, failure torque, current shift inclination, electromagnetic saturation, and so on. As a consequence of the quantitative evaluation of the obtained SPIMs and the discussion of results, beneficial conclusions were formed.

To summarize, the study sheds light on the creation of capacitor-run SPIMs with improved efficiency, while also addressing issues such as the influence of contact resistance on rotor ohmic losses and the impact of capacitance on the motor's magnetizing inductance.

Chasiotis, I.D.; Karnavas, Y.L.; Scuiller, F. Effect of Rotor Bars Shape on the Single-Phase Induction Motors Performance: An Analysis toward Their Efficiency Improvement. Energies 2022. 15(3). 717. Available at: https://www.mdpi.com/1996-1073/15/3/717/htm

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.

Ibtisam graduated from the Institute of Space Technology, Islamabad with a B.S. in Aerospace Engineering. During his academic career, he has worked on several research projects and has successfully managed several co-curricular events such as the International World Space Week and the International Conference on Aerospace Engineering. Having won an English prose competition during his undergraduate degree, Ibtisam has always been keenly interested in research, writing, and editing. Soon after his graduation, he joined AzoNetwork as a freelancer to sharpen his skills. Ibtisam loves to travel, especially visiting the countryside. He has always been a sports fan and loves to watch tennis, soccer, and cricket. Born in Pakistan, Ibtisam one day hopes to travel all over the world.

Please use one of the following formats to cite this article in your essay, paper or report:

Abbasi, Ibtisam. (2022, January 20). Improving the Efficiency of Single-Phase Induction Motors with Rotor Bars Shape. AZoM. Retrieved on June 05, 2024 from https://www.azom.com/news.aspx?newsID=57958.

Abbasi, Ibtisam. "Improving the Efficiency of Single-Phase Induction Motors with Rotor Bars Shape". AZoM. 05 June 2024. <https://www.azom.com/news.aspx?newsID=57958>.

Abbasi, Ibtisam. "Improving the Efficiency of Single-Phase Induction Motors with Rotor Bars Shape". AZoM. https://www.azom.com/news.aspx?newsID=57958. (accessed June 05, 2024).

Abbasi, Ibtisam. 2022. Improving the Efficiency of Single-Phase Induction Motors with Rotor Bars Shape. AZoM, viewed 05 June 2024, https://www.azom.com/news.aspx?newsID=57958.

Do you have a review, update or anything you would like to add to this news story?

In this interview, Michael Allen, the Vice President of Products and Marketing at Metrohm Spectro, Inc., talks to AZoM about Raman spectroscopy and how it can be used in biomedical applications and sustainable farming.

In this interview conducted at Pittcon 2024 in San Diego, we spoke to Seth Lyman about atmospheric mercury, exploring innovative measurement techniques, and the environmental impact of mercury pollution.

In an interview following ChemUK 2024, we spoke with Dr. Alan Wiles, Director of Operations for ScotChem. He discussed the organization's mission, significant community impact, and ongoing efforts to enhance innovation and collaboration within Scotland's chemical sciences sector.

This product offers a versatile platform for Airborne Molecular Contaminations (AMC) monitoring in a variety of semiconductor applications like FOUP analysis and cleanroom-monitoring.

Empower Materials presents QPAC® polyalkylene carbonate binders for nano silver sintering paste used in the die attach process in semiconductor manufacturing.

This product profile describes the features and applications of the microArch D1025, a hybrid resolution 3D printer.

The global semiconductor market has entered an exciting period. Demand for chip technology is both driving the industry as well as hindering it, with current chip shortages predicted to last for some time. Current trends will likely shape the future of the industry, which is set to continue to show

The primary distinction between graphene-based batteries and solid-state batteries lies in the composition of either electrode. Although the cathode is commonly changed, carbon allotropes can also be employed in fabricating anodes.

In recent years, the IoT is rapidly being introduced into almost all sectors, but it has particular importance in the EV industry.

Your AI Powered Scientific Assistant

Hi, I'm Azthena, you can trust me to find commercial scientific answers from AZoNetwork.com.

A few things you need to know before we start. Please read and accept to continue.

Azthena may occasionally provide inaccurate responses. Read the full terms.

While we only use edited and approved content for Azthena answers, it may on occasions provide incorrect responses. Please confirm any data provided with the related suppliers or authors. We do not provide medical advice, if you search for medical information you must always consult a medical professional before acting on any information provided.

Your questions, but not your email details will be shared with OpenAI and retained for 30 days in accordance with their privacy principles.

Please do not ask questions that use sensitive or confidential information.

Read the full Terms & Conditions.

AZoM.com - An AZoNetwork Site

Electromagnetic Brake Owned and operated by AZoNetwork, © 2000-2024