ToyBox touts intuitive app and simplicity of design to introduce kids to the wonders of 3D printing their own toys. Image courtesy of ToyBox Labs.

Imagine the joy on a child’s face when they unwrap their favorite action hero who happens to have their same tousled hair and toothy grin. Or what about the litany of abandoned toys that suddenly become whole again by recreating missing or broken parts? Injection Molded Seat

These scenarios, along with new on-demand and in-home production business models, are the current and future state of the multi-billion-dollar toy industry thanks to the maturation of 3D printing. Hardware advances, persistent cost reductions and broader materials choices are coalescing to make 3D printing a viable option for some forms of toy production, not to mention more realistic and effective prototyping.

“Toy manufacturers are transitioning their focus to a more customized, user-centric approach to product development,” says Gary Rowe, global head of business development at Formlabs. Formlabs has formed a partnership with toy giant Hasbro to leverage 3D printing to deliver unique experiences, including the Selfie Series project to create custom action figures. “This approach, which can be executed with 3D printing, is meant to deepen the customer connection and strengthen brand loyalty,” he says.

The time is right for 3D printing to have an impact on toy manufacturing for various reasons. Consumer-grade 3D printers have arrived at a price point and offer out-of-box configuration and deployment simplicity that allow parents and kids to create and output customized toys without a lot of hand-holding.

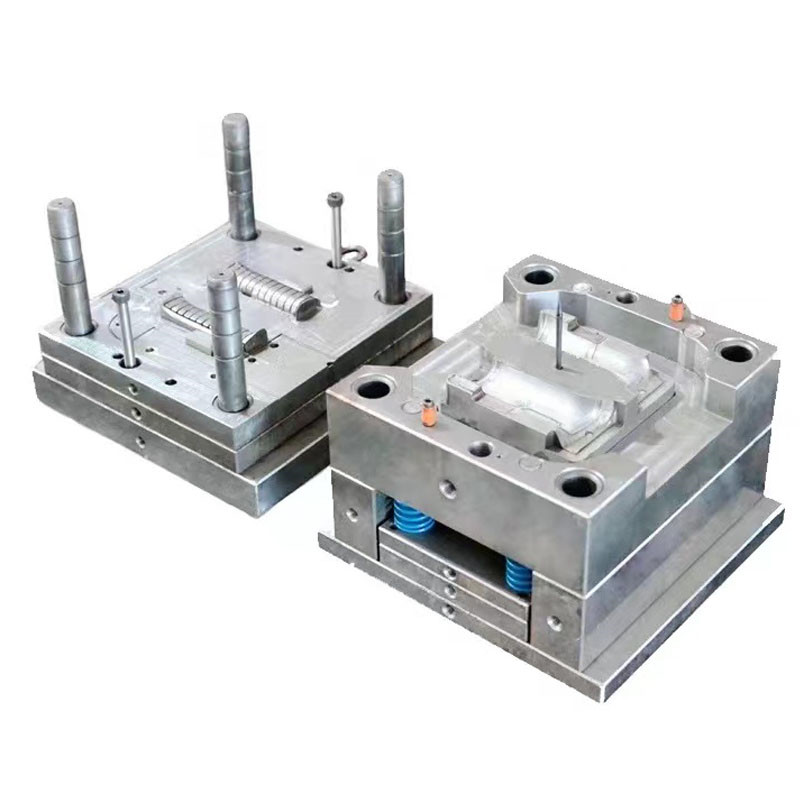

For manufacturers, 3D printing systems can mitigate the cost and pain points of traditional injection-molded processes, which don’t necessarily make smart business sense for custom offerings with limited demand and a relatively short shelf life. The combination of large-scale 3D printers and online design and ecommerce platforms also can open the door to new on-demand channels for product sales. With this approach, toy makers can sell new product lines without the cost of packaging and maintaining product inventory while also benefiting from sustainability advantages such as reducing the carbon footprint typically associated with complex supply chains.

Several years ago, a team of engineers from Michigan Technological University and MyMiniFactory, an online platform and open ecosystem for 3D creators to share 3D printable files, set out to evaluate the economic impact of 3D printing on the toy manufacturing industry, which was projected to be around $135 billion in 2020. Their report, based on the 100 most popular downloaded designs at MyMiniFactory, produced using a Lulzbot Mini 3D printer and three filament types, found that a single 3D printing repository supporting dozens of people could save consumers over $60 million a year in offset purchases. The most cost savings fell between 40% and 90% in total savings—a result of being able to make novel toys and games not readily available elsewhere.

“The results show consumers can generate higher value items for less money using the open source distributed manufacturing paradigm,” the survey concluded. “It appears clear that consumer do-it-yourself manufacturing is set to have a significant impact on the toy and game markets in the future.”

For now, 3D printing’s effect on the toy industry is somewhat limited, but shaping up in interesting ways. Major manufacturers like Mattel, Hasbro and Lego have toyed with some 3D printing-related projects, but have yet to incorporate 3D printing into mainstream production practices in any significant fashion. For example, Mattel had plans to resurrect its 1970s ThingMaker mold and bake creation toy with a 3D printer variation, but after announcing the product in 2016 with great fanfare, it ended up postponing and eventually scuttling the project.

Mattel had entered the realm through a partnership with Autodesk to create an immersive experience that bridges the physical and virtual worlds using 3D printing, but that too was a short-lived experiment. Currently, Mattel isn’t using 3D printing for mass production applications, although individual engineers are leveraging the technology to concept, design and engineer the toys of the future. While not yet leveraging 3D printing for its own production, there is a giant open source community devoted to resources and advice aimed at helping users and would-be toy designers 3D print Legos, customized designs and replacement parts.

One-off toy builders and smaller manufacturers are more committed to 3D printing. Consider Nick Hardman’s 3DToyShop, a nonprofit started by the hobbyist to leverage 3D design software and 3D printing to make accessible toys for kids. The first products were custom teddy bears wearing 3D printed replicas of medical devices so kids having to wear the real-world counterparts would feel more comfortable with their treatment—what Hardman described as “taking the fear away from medical devices through play.” There’s a Teddy Shunt Valve, a toy designed for kids with hydrocephalus, which has been safety tested with a fully compliant design that meets European Union toy safety laws. There’s also a Lego man with a prosthetic arm and a teddy bear that wears a tracheostomy.

Among major toy manufacturers, Hasbro is at the forefront of integrating 3D printing into its product strategy. The company, which had been using 3D printing to prototype new designs, discovered its potential for using the medium to deliver a mass customized product. Enter the Hasbro Selfie Series, a project where Hasbro enlists Formlabs 3D printers to create personalized Power Rangers, Stormtroopers, Spiderman and other action figures. Fans download the Hasbro Plus mobile app to scan their face and customize their character. The collector-grade, 6-in. customized figures are printed out using a fleet of Form 3 stereolithography (SLA) Formlabs printers and then shipped to the customer’s doorstep.

As part of their collaboration, Formlabs developed a new resin for the project based on Tough 1500 material so it would meet quality assurance and safety standards and adapt to a broad range of skin tones and hair colors. In addition, the pair developed a custom-designed digital workflow that would accommodate the needs of this particular application.

“To effectively use additive manufacturing [AM] for toy production, manufacturers need hardware, software and materials that are designed to work together,” Formlabs’ Rowe says. “Without every factor working in harmony, production will not be seamless, high quality and fast enough to suit the demands of mass customization.”

Toybox Labs, once a Shark Tank contestant, is taking a different approach to 3D printed toys. As opposed to building out 3D printing farms to produce custom toys, Toybox launched its own 3D printer and online platform marketed as simple enough to let kids output toys at home. The Toybox one-touch 3D printer, priced at $349 for a deluxe bundle, was designed from the ground up to be easy to use—more like an appliance versus the hobbyist consumer-grade 3D printers that were popular at the time, according to Ben Baltes, co-founder and CEO.

Simplicity guided all of the company’s design choices for the printer—for example, the Easy-Peel bed that makes it easier to release models and parts from the bed as well as polylactic acid materials specifically designed to work seamlessly and safely with the hardware, Baltes says. The printer is accompanied by an online platform and library of over 3,000 toys; users simply select what they want from the accompanying app or on the Toybox website and the model is sent to the printer, preconfigured with the right slicer settings and ready to print. There is also a Creator Studio option that lets users create their own figures using CAD software and importing models in STL, OBJ and gCode formats.

“Users see what they want, press a button and the configuration is taken care of on our end,” he explains.

Not only is Toybox an accessible 3D printer for kids, Balte claims the model highlights how AM technologies need to evolve to gain mass market acceptance. “This what the future of 3D printing looks like—bringing down the learning curve and the ability to use the device without having to be an expert,” Baltes says.

Most in the toy sector don’t view 3D printing as a replacement for traditional production methods, but rather envision a hybrid scenario where 3D printing is used for broad experimentation with traditional casting and injection molding methods employed for large-scale production. While 3D printing has always been a prototyping tool, more powerful and lower cost desktop printers, coupled with expanding materials choices, now enable designers to create prototypes that not only look good, but mimic the function of the end-result toy, according to Luis Rodriguez, applications engineer for Makerbot, now part of Ultimaker.

For example, Ultimaker’s S Series of printers combine ease of use with versatility, allowing users to choose from up to 280 materials to meet a wide range of requirements. The S5 and S7, in particular, are used by many design houses working with toy companies to create realistic, functional prototypes, he says. “Instead of using a paper form core or older 3D printing technology, designers can now afford to iterate daily or hourly because the technology is so accessible and is lower cost,” Rodriguez explains. “It allows [toy] designers to see what sticks, not have to pick one thing to explore with prototyping technology. On one build plate, they can have 10 iterations and see what works.”

The Method 3D printer, originally introduced by Makerbot, offers a heated build chamber, direct drive and rigid metal frame that, together with a robust suite of engineering-grade materials, are well suited for building highly repeatable, accurate prototypes or end use parts.

“In many cases, you want to mimic and use the same material you use in production so you can evaluate dimensional accuracy or see a real-world representation of how the toy functions or snaps together,” Rodriguez adds. There is also no need for a lot of post-processing work like drilling out holes or sanding. “The parts come out accurate and strong so engineers can stick to their job of designing and engineering rather than shoehorning the prototype to be what they want,” he adds.

In the end, it boils down to the marriage of software, hardware and materials that will ultimately increase 3D printing’s impact on toy production. “People don’t want to worry about troubleshooting a printer, they just want to worry about being a toy engineer,” Rodriguez says. “3D printing needs to let them produce anything they dream up. The technology can’t be a hinderance.”

Plastic Injection Mold Price Beth Stackpole is a contributing editor to Digital Engineering. Send e-mail about this article to [email protected] .