If you’ve ever wanted to forge, cast, or smelt metal, this project is right up your alley. It’s a 30 kVA induction heater built by [bwang] over on Instructables. It gets hot enough to melt and forge steel, iron, and aluminum.

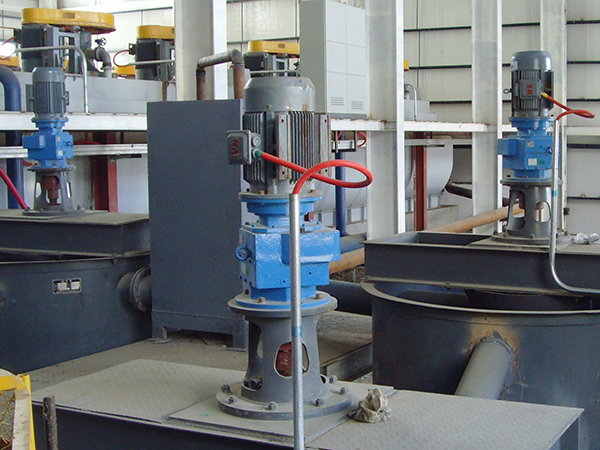

An induction heater operates by surrounding the object to be heated with a coil carrying high frequency AC current. Basically, the entire setup acts like a huge transformer with a shorted secondary. To get these currents into a workpiece, [bwang] used a TL494 PWM controller as an oscillator. The output of the TL494 is filtered and amplified a few times to generate a huge amount of AC current. Pb Oxidized Ore Collector

Larger versions of [bwang]’s induction heater are found in foundries and forges all across the land; even though this small version sucks down 50 A out of a dryer or stove outlet, induction heating is very efficient. We’re actually wondering why we don’t see many home blacksmiths using induction heating, so we’ll leave that for our readers to discuss in the comments.

[sessions] reminded us of this induction heater from a few years ago. A little smaller, but still usable.

We’re actually wondering why we don’t see many home blacksmiths using induction heating

Propane is portable, relatively cheap, and has a lower start up cost.

Many home brew black smith shops don’t look into the current method, they look at the traditional methods of iron working. Also most people have a fear of electricity. I guess people like to see what might kill them. More seriously, you know that a propane torch will get hot, and it will allow you to work you piece, if someone told me to hook up some random electronics together and it will heat up my piece really quickly, and it will save me money in energy. i would be skeptical. Sounds like snake oil to me (well not really i know how it works, generating eddy currents and what not but forget all of the science for a second)

The components are not random.

if somebody told me that masterfully crafted ceremonial sword was crafted by a guy with a hammer and a 3000 degree forge in a dirty shop somewhere in the poor side of town, or industrial park district… I’d be skeptical…!

I’m an EE major, network administrator, ham-radio-operator, former construction worker, who’s #1 hobby is metalworking.. that makes me about the only guy street-cred- qualified to make the aforementioned quip…! :-p

Oh! and I’m here looking for how-to on getting started with induction furnaces for smelting steel, iron, bronze and brass for casting…

Smelting or melting? There’s a big difference between the two.

KC, did you ever get started on this? Your ‘street-cred’ I can comprehend and appreciate. Thanks.

K9SPY, I was wondering if you ever got an induction forge off the ground? I’m in a semi similar situation, EE enthusiast (no degree sadly) and a software engineer. I love the idea of using energy fields and what I’m assuming would be in essence a HF EM generator to heat metal for WORKING. I recently inherited a truckload of old tube based radio gear so I need to study up to get my extra class license, but knife forging is one of my new hobbies, and I’m always looking for new cool ways to get things done.

And electricity is available in almost all homes these days and doesn’t need a tank to carry round, you just need a wire to move around…

I picked up a faulty induction hob for free and it cost me a couple of quid in power transistors to fix. I did wonder if I could use it for metal melting but if there is a decent write up of how to build a melter from scratch, I could keep the hob for making dinner.

Despite the ubiquity of residential electrical service, there’s still a lot of issues with using it for this type of work that scares people off (namely electrical codes, homeowner’s insurance, and as others have mentioned the inability to see the thing that could fry you in an instant if you do something wrong). Plus this setup doesn’t seem like it could melt an appreciable enough amount of metal in one batch to cast anything of any significant size. Forging would probably be a bit awkward too, since the size and shape of the coil would limit the workpiece. Something like this would be fantastic for working with jewelry though, since that involves smaller amounts of metal.

If you want to see how to build a real foundry/forge on the cheap, get a catalog from Lindsay Publications and see what they have to offer. Their offerings are much lower tech, but they definitely qualify as “really old school” hacking.

This is the same thing the industrial foundries use so what are you talking about you couldn’t melt down enough to make any sizable piece ?

I checked the date on your post, 7 years have passed and I can’t find a Lindsay’s catalog anymore. I remember looking through their stuff with awe but as a 15 year old I could neither afford their books nor convince my parents to let me try anything. I imagine that archive.org and the internet in general took a lot of Lindsay’s business away, but I would love to get some scans of their catalog – anyone? -thanks!

https://openlibrary.org/publishers/Lindsay_Publications

Open library has a few

Induction heaters use around 26-30 khz heating a steel crucible, at around 100-220 volts. Only thyristors or high power tubes can switch this kind of voltage, to make an iron forge like this, you would probably need a Royer-type power oscillator using two transmitter tubes, and a high anode voltage maybe up to 1kv., or a thyristor multivibrator switching 220v., at 30 khz.

huh? MOSFETs or IGBT’s will work, a GANfet could switch 5kW with a single 5mmx2mm integrated half bridge

Propane does not burn hot enough for many flux welding applications, it will heat the metal to a malleable state without ever burning the metal but coal/coke forges allow for much higher temperatures that make flux welding much easier. Depending on how you do it, the start up costs of a traditional forge can actually be less than that of a propane/gas forge

Propane its self may not get too hot but a propane forge is not just propane. It is propane shot into a well insulated forge shell (ie: Kaowool). My forge is propane and it is more than capable of burning a 1095 billet into a puddle of useless slag.

Same with mine, I have two propane fired forges, one is the pipe style forge insulated with kaowool, the other is one of those artist forges with high temperature tile on the top and bottom, I have melted some projects in both of them! Especially when I was transitioning from coke to propane, I wasn’t used to the dragons breath or how bright the forge would be so ended up misjudging my temperature a few times!

my three burner home built propane forge has a max operating temp of 2625 while my five burner home built forge with cap out my thermometer at 3250…so in conclusion this statement would be incorrect sir.

I have, and know others that forge weld with propane. Forge welded a couple of cable knives in about ‘84.

Last time I checked, blacksmiths are not known for their portability. Moving anvils isn’t easy. Last time I also checked, blacksmiths don’t exactly setup and move quickly. Most take time to learn then practice their craft. Keeping costs low is always a generally good trait to have but propane tanks cost money too as do quality blacksmith tools. I don’t buy your argument.

Blacksmiths shoe horses. Saw a guy do it out of a pick up truck. Had an anvil and everything. Couldn’t have been more than a thousand bucks worth of propane forge and tools.

Farriers shoe horses. It is an extremely specialized subset of blacksmithing. A well-equiped smithy will have tongs for every shape and size of material, then specialized tongs to, say, keep the eye of a hammer or axe from closing. It will also have hammers in three of four sizes of EACH of the common shapes (cross peen, straight peen, ball peen, round faced hammers, and sledges), then there are all of the various hardy tools for cutting, fullering, rounding, banding… The list goes on. A farrier buys his shoes, then modifies them for the horse being shoed at the time. That doesn’t take very many tools. A blacksmith is known for making a tool for a specific job, and at times, making a tool to make a tool to do a job.

not quite so, some farriers still make shoes out of a bar of iron or soft steel, some will buy the pre-made, usually those who went to a trade school to learn their craft and not the old fashioned apprenticeship with the master farrier.

That would have been a farrier

Regarding the comment that blacksmiths shoe horses: Wrong. Farriers shoe horses. They have (or should have) special training in a very technical subject — the anatomy of various animal hooves, and the injuries and diseases thereof, and the modes of treatment that can be applied through specially constructed shoes. Blacksmiths may sometimes make horseshoes, but they are more likely to make many other things as well. Farriers, not so much in my experience.

It’s kind of like the difference between a gunsmith and a machinist. Different specializations and knowledge domains, similar skills and tools.

I was a working blacksmith for a while some years ago (at a local historical park and for a summer at a nearby Renaissance Fair — I spent that year commuting between 1562, 1845, and 1992. Hard to keep the accents straight.)

The man I learned from spent twenty or so years as a machinist before he retired and became a farrier, and then did that for a bunch of years until he got tired of looking at horses’ hooves so he focused on blacksmithing and training blacksmiths.

Actually ‘farrier’ just means a metal worker in french and before we got all posh our iron workers would advertise as ‘smith & general shoeing (of horses of course! )

Farriers move around a lot.

Way, way lower. I use propane and charcoal. cost me about $40. I definitely want to build an induction heater one day, but that day is not here yet.

The cheapest Chinese machines of a suitable size for blacksmithing are $2,000. American are about 2 times that. I am a hobby smith in Washington State. Grant Sarver, a noted smith and tool maker in our the Northwest Blacksmith Association, started selling and promoting these machines years ago. They are fairly commonly used by professional smiths here. They lend themselves to specific purposes related to the size and shape of the piece of stock being heated. Well equipped smiths who can afford extensive tooling use induction heaters as part of several other heating methods. Propane forges can and do reach welding temperatures, but are limited by chamber and burner size as well. Coal definitely reaches weld temperature easily, but forge welding is not exclusively or perhaps even frequently used. It requires more skill than arc welding, and a heated and hammered arc weld is almost indistinguishable from a forge weld. As a hobby smith I would like to have an induction heater, but I will have to build it for expense reasons alone. That’s fine because it’s bound to be an interesting, exciting, educational experience.

not sure what machines you are using but i have a coal forge, two propane forges, 2×72 belt grinder 4×36 belt sander a few different other tabletop grinders, a hammer press, 200 lb hay budden anvil, 3 post vice and a 50 ton press, plus tongs and hammers and various other jigs and tools…i might have $2000 in all of it and can pretty much make anything you want.

Ahat 2×72 do you have, or did you build it? Because a 2×72 will run you damn near $2k on it’s own.

1. A properly set up induction forge that will not KILL YOU and is the cheapest (and weakest) Is 5-7 thousand US$. A lot of blacksmiths use a simple brake drum forge,coal, and supplied air and it costs pennies per heat where as this is more expensive because of the massive start up cost and crazy electric bills. Propane also just requires a box with fiberglass insulation, a propane tank, and a burner. This is to expensive and you can only work pieces small enough to fit inside the rings, where as a traditional coal forge you could heat 20lbs of steel in it given enough time and coal.

The induction coil needs to be of a specific size. When you are forging you might have pieces that are apparently random, depending on what you are building. Therefore this electrical approach is not practical…

You do know the coils are easy to make and only need to be an approximate size to work right. Easy to use online calcs will easily give you a good enough ballpark to make your coils. I use compression fittings and a variety of coils I made myself of different sizes and shapes for both forging and melting. I’m hoping one day I can make one with the right power and structure to melt inconel for a couple projects I have.

I know this post if from 3 years ago, but one thing about electricity: where I am in Canada it is VERY expensive….for example: it costs me about $2.00 in propane to melt about 8 lbs of aluminum…..in electricity it would cost me about $17.00….now I don’t know how long it would take for a 50A 220 volt induction forge to melt the same, I’m basing this on approximately an hour’s time for each method…to top it off, my rates are going up yet again next month so the cost will be even higher…..

pure math says 1kg = 37mol of Alu * 24.2 J/Mol Kelvin = 896.3 J/Mol Kevin * 600 Kevin temp increase = 538 kJ /kg of Al to melt…. / 220 V / 30 A = 81.5 seconds to melt. ()

17.00 in electricity in canada at the highest rate in canada is about 0.17/kwh so you would need to have a inductive forge that is 10kw run for 10 hours

From memory electrical heating metal has been around for many years and I remember reading an article where it was used in a workshop. I don’t recall the exact method used but I do remember it employed an oak barrel and a high current.

As a blacksmith I see issues with induction heating firstly in many cases your steel is not straight. in addition I have to wonder what heating the in a strong magnetic field is like to do the the grain of the metal.

Something to ask yourself is “Why has the traditions not changed much over thousands of years” in addition much of the hand forged work using traditional methods tends to last a lot longer sue to the introduction of silicates and carbon as part of the forging process and using induction you would not get this.

We dug up some tram parts and blacksmith tools that were burred for 60 odd years. these were pulled out, cleaned up and are almost as good as new. The same went for the Mastermyr find. http://netlabs.net/~osan/Mastermyr/

Items made even in propane forges do not tend to last as long or exhibit the same quality as those made using traditional methods.

However these types of devices would be perfect for some of the forging process such as rivet making, bolt making etc.

I bet you still ride your horse to the market.

As a knife maker who has used both charcoal, propane, and induction I can say that there is no comparison in the quality, the more modern the method the greater the resulting quality. Induction does nothing to the crystal grains, as soon as you reach austenitic temps your steel doesn’t interact with magnets. In addition the current is constantly switching so there is not really any way that it would affect the crystals.

I’ve seen gas forged chisels hardened and tempered, machined to accept carbides which were braised in an induction field. We always wondered if that frequency was a contributing factor to that operators diminishing mental health.

Dude electricity as a whole has only been around for a couple hundred years aka why things havent changed that much in so long, is because overall electricity/electrical forges havent been around that long when compared to when people first started working metals in history it’s still in its infancy.

The neat thing about this is being able to do it in an apartment.

Anyone have any induction korean bbq tips?

korean bbq, use a hair dryer for blower with hunk of exhaust pipe to kingsford (or other) charcoal. YES, it works. still need the anvil and quench, but five gallon bucket should work for quench. kids play pool with play sand to catch slag on your patio to house the anvil area. fire extinguisher available ‘just in case’ and a 12 pack of beer for the nosey neighbor with a cell phone on his hip. VIOLA!

The use of coal adds carbon into the metalworking process which controls a few factors in the end product. You would lose a lot of control with the use of other methods of heating.

I’m friends with quite a few art knife makers who specialize in damascus and there are more professionals who own inductive forges than this article implies. Cost isn’t usually an issue for the big guys, they have huge write offs each year. The big issue is relearning the forging process on these inductive units. These guys have grown accustomed to using fired forges over years of work and have a developed feel for their equipment. I would prefer induction hands down…gas forges are loud, hot, and bright. When I’m over at my friends forging, it takes me quite a while to get over the vision issue alone.

I would love one of these for heat treating watchmaking parts- but I fear it would be overkill! Can anyone tell me if it is all out heating, or can you control the power output- so say, I could heat up a screw or barrel arbor to cherry red, and keep it there with a constant power output for a couple minutes?

If not, the idea that I could melt STEEL in my apartment is f*ing incredible. Not everyone wants to deal with expensive propane or dedicate an entire side of their house to a huge propane forge grill or something like a blacksmithy to melt steel.

I have a guy right now with a Levin instrument lathe and full watchmaker’s workshop in his kitchen- he would kill for one of these for small quantity metal melting in a compact form. This is awesome! Totally why I come to hackaday multiple times a day for years now.

From the perspective of an apartment owner or even neighbor, the concept of my tenants melting steel INSIDE THEIR APARTMENT seems somewhat terrifying at first glance.

You forgot that for all intents and purposes it becomes their apartment when you sign the lease, what they do inside is their business. If they cause damage, then take it out of their deposit. And how about all the fires started every year from deep frying, cooking, cigarettes, etc?

Unfortunately, in Canada, there is no “security deposit” for apartments. Any damages will be recovered by the owner, when he takes you to court.

This has got to be the most idiotic statement ever made.

Since it’s electrical, I imagine you could use some PWM to control the temperature.

At the foundries,we not only had the 10 megawatt furnace melting 10ton batches,but the mechanics also had a tabletop unit to heat bearings while fitting them on and off shafts.

Snap-On sells little portable induction heaters to make the removal of bolts easier than using a torch in tight spaces(I.E. – under the hood of a car or inside the car even.) It’s called the Mini-Ductor II:

http://blog.toolsource.com/index.php/2010/07/mini-ductor-ii-magnetic-induction-heater-kit/

14 oz of propane cost me less than ~2oz of butane.. gets me a few days of playing with melting glass being very wasteful. still, for metal, playing with dangerous voltages and eddy currents piques my interest. i think i will build one of these sometime. i’d like to see just how small I could reproduce this, retaining the functionality.

I just wish I didn’t live in an apartment so I could use ANY method available to melt aluminium for casting. :|

As it is, I’m saving all my scraps and stuff from my beginner’s practice with turning and milling, so I can one day melt them down. :o

two years ago we had a similar post.

could you add a link to the article in the post?

Induction forging and melting got its foothold in the speciality metals market where the presence of the exit gases from coal/coke/Nat Gas would effect the characteristics of the metal. If you want to melt large gobs of metal quickly and still use juice, then electric arc furnaces are the ticket.

In the US, not all houses/apartments have 220v 50w outlets, and getting an electrician to install them can be absurdly expensive. Also, if you want to be portable, nothing beats a nice cylinder of propane or acetylene for making heat, though if someone could do a hack using a Prius to power a portable induction heater…

will this incuction heater ,melt platnium?

Yes. Anything that conducts current. But some metals may “burn off” ,oxidize, &c… at smelting temperatures. I’ve never melted platinum, so I’m not sure of the environment it needs to stay intact.

Would there be a concern with crucible material? I know that graphite is incredibly conductive so I would be more afraid of the crucible type being used, I’ve been using a 100W CO2 laser with focusing lens to melt the more precious metals in a vacuum! (I have a lot of natural copper, gold, silver, etc in my stream sediment, electrochemistry gets the metals, but it makes them into a mixed slime that coats my graphite cathode!) The induction concept would have less dangers associated with it than a laser beam that may reflect.

I’m sure your not melting stolen CATs.

will this particulat induction furnace melt platnium?

So… Induction heating is broadly used in foundries. So if the metal you are using came from a modern foundry, it probably already has any inherent issues that might be imbued upon it present when you buy it. Granted, these are generally at melt point temperatures. I can see some concern with this, but have never seen any issues. To be honest, what are you forging that this could be an issue?… As far as electrical shock goes, high current, high frequency low voltage has the same dangers as arc welding. If you aren’t comfortable with the electrical apparatus in the cabinet, then don’t build it. Size limitations, yes. But to forge something small, why waste the resources firing up the furnace. You can use it for smelting, annealing, and forging. The coil to induce the current is easy to make, so to be somewhat malleable in respect to application. As far as not adding carbon to the metal, this should be an advantage to controlling the addition of carbon. Adding carbon should be done in the hardening process. You should heat the part of the work you are not putting the hammer to, in order to maintain an even heat in the work…. For several reasons. I think it is a good addition to a shop. I’m a machinist by trade, and induction annealing is a great tool for us. Beats the pants off of a MAP gas torch.

Correct me if I’m wrong, but this works by inducing an electric current in the conducting metal causing what is essentially, a short circuit. I don’t think it would have the same effect on biological tissue. So, if the conductors are properly insulated, this might also be more touch-safe than a propane torch.

The long term effects of living in strong magnetic fields is not well known. But there is much evidence to suggest that high tension power lines are detrimental physiologically. Induction furnaces run at a similar hertz, but much higher strength.

I wouldn’t be worried using one occasionally, but it may cause problems for someone who uses it every day for a living.

I thought that power transmission was at about 50-60hz while induction heating is usually at least a thousand times that much.

You are wrong. An induction coil induces eddy currents into the metal which agitate the molecular bonds. The heat generated by this action could cause melting of the material inside the induction coil. The coil will heat up as a result of heat transferred back from the material being heated. The induction coil would otherwise be cool during operation if no material is inserted into the coil.

I have thought about trying induction heating but I don’t think it would really be practical for my specific specialization. I usually forge curved or generally large objects, scythe blades and axe heads for example. I would think that any induction unit would be similar to a torch in that it would spot heat, and would possibly warp a project if great care wasn’t taken, but I do not know, I feel this technology holds a lot of promise, however. On the topic of casting, I have the same concern, for iron and aluminum in most cases one would want to melt a relatively large amount, and pour all at once. I have been welding and have worked in several machine shops, as well as been into casting and forging for quite some time, I believe every situation would be different. For people who recycle gold and other precious metals that don’t want bulk, I feel it would be ideal! I’ve been recovering gold, nickel, silver, copper etc from ash with electrochemistry and feel the induction melting would be the best method of separating them out. I’ve been using a focused 100 watt CO2 laser to melt those materials and burn off carbons without introducing any additional contaminants, I would be much more comfortable with induction heating. When you have a chance of reflecting an invisible laser beam, you’re gonna have a bad time! I don’t see why it wouldn’t be possible to control temperature precisely with induction to make life a little easier for smelting and eventually casting as well. Anything bulk though I would stick to using the traditional bulk melt crucible or cupola.

They were one with the first companies that created watches competent at showing times in several time zones, too as altitude, GPS position and temperature. If you plan on sometimes a small G Shock lineup, make sure to shop around to ensure you usually takes your budget far. Kikuo Ibe, and the watch was designed to absorb the shocks and turbulence from a sport or outdoor activity.

Doesn’t the material around the coil get HOT too? Most of the mini-ductors cost around $700-$1000 U.S. and the coils don’t exceed 2″ inside and working length of 50 to 65 mm

Coal doesn’t add carbon to low carbon steel if anything it will case harden that’s all so induction would be as good as coal or propane .

I use a coal forge because induction or propane limit the size of the object I can heat.

if you only wanted to get the metal up to 475 degrees would you limit the volts in?

is it possible to heat up two different types of metal with one of these to 475 degrees let’s say 40 lbs of stainless steel and copper? can a solenoid control the power to turn it off and on in a pulse?

a little true knowledge on this subject. the heating charachteristics and coupling are effected by the frequency of operation. low frequency is used for deep penetration and melting efficiently. even 60hz(scr generator, or triac) in a very large melting unit. 2 to 5 mhz(tube) units have been used for carbide and surface hardening. 30-100 khz units from china are good for general purpose rapid heating and melting. a little advice 1. learn to calculate the necessary RATE of heating(watts induced in the load). do not forget about inverter or coupling efficiency. 2. different metals have different conductivities. you may want more turns for copper than graphite. 3. some metals are magnetic, but this property drops off as you approach the curie point. 4. the closer your metal is to the coil, the more efficient your coupling is. 5. use of magnetic materials (ferrites, mu metal, etc depending on frequency and desired effect) to concentrate or shield parts of your load can be helpful. 6. at the melting point of steel, regular crucibles can and do “hot spot”. small areas of some materials become ionic, and therefore conductive. these areas can and do melt. put a sand box under your load in case this happens(crucibles also break) 7. if your induction heater has a frequency range, you may want to get a meter that reads inductance. wavetek used to make a dm27xt for about $100 that has usual useful ranges+capacitance+inductance+frequency not sure who makes what today. there is a capacitor in parallel with your coil(inside the induction heater). you want these to be in resonance at a frequency your induction heater can handle. the mfg should specify a safe range of inductance. if heating steel …….curie point…. 8. 3 common ways to control power are 1) varying voltage to the tank cicuit 2) turning the whole circuit on and off 3) at line frequencies(50/60z +/-), the phase of scr firing

this is just the basics

As both a blacksmith and foundryman Well said.

I have a small induction furnace the type used by a dentist I couldn’t resist buying at a pawn shop. And sandcast brass, bronze and zinc from a large Radyne water-cooled unit where the crucible was hydraulically lifted up to floor level for the crane. While the same in theory https://radyne.com/what-is-induction-heating-2/induction-heating-basics/ the sheer difference in power density and control is immense. There are a lot of variables for both the metal and size of crucible.

From the blacksmithing side. Whatever fuel is used it has a time component in heat flux. For a closed forge how well insulated and what massflow will determine maximum temperature for a given volume. As an example of what I mean I needed to straighten a bent forklift time for a tractor. (I know it ruined the temper but the friend wasn’t reasonable about that) While he thought an smallish Oxy-acetylene rosebud could get a 2″x4″ time to working temperature outside in winter I knew better. A simple pit with a drilled rectangular steel tube a couple of bricks and a blower quickly reduced some old coal to coke and was able to transfer enough heat to work it rather than have it wicked away.

The same would be true for this project. If inside a closed forge with good insulation.the ability to get more of the work to working temperature would increase.

By closed – a box with only one wall open or with a window in it or through it. I’ve worked a dedicated propane forge with a small window through it just for chiseling/upsetting/twisting balusters.

i think people are slow to change. people fear change… induction is a good thing. and much faster for heating or welding… if i could afford one i would buy one.. i am 50 and i love working at a fire and swinging a hammer.. i dont care where the heat comes from though i do love to see flames.. if i got an induction heater i would prolly have a picture of flames near it :)

“We’re actually wondering why we don’t see many home blacksmiths using induction heating” I can only speak for myself here, but the main/only reason why I don’t build and use an induction forge is that NOBODY SEEMS ABLE TO PROVIDE SIMPLE INSTRUCTIONS HOW. I am not an electrical engineer for the simple reason that, despite a near-genius-level IQ, all of that EE Greek-Speak is apparently too much for my simple craftsman/artisan brain. (Seriously, when they hand you guys your degree do they make you sign an oath to never speak plain English again?). I would very much love to build an induction forge and can readily see the advantages of it. But every time I start scouring the internet for how-to’s, every video and instructional follows the same pattern of spewing out a bunch of Greek and acronyms and breezing through the build with the assumption that all of us dumb bumpkins have the slightest idea what they just said. Seriously, I got about a third of the way through the Bill of Materials before my brain said “F* this, my waste oil forge works just fine.” We get it, You guys are electrical engineers… you’re very smart and educated, congratulations. But honestly, this isn’t a starship you are building – with all that education and experience at least one of you ought to be able to make a reasonably intelligent lay-person understand what on earth you are saying. I would venture to guess that the main reason why most of us stick with coal, propane, or waste oil is that one does not need to learn a whole new language to use coal, propane, or waste oil.

One sign of a truly skilled and knowledgeable person is that they can make themselves clearly understood to just about anyone.

wow thats a read and a half. i have an ongoing induction furnace project that has been going for about four or five years now. i have got as far as a separate, insulated, tilting coil and crucible (graphite 4″) from which i have succfessfully poured aluminium, copper, brass, bronze and yes iron.

the learning curve is steep, i have some qualifications in maths, physics and electronics but nothing to degree level and many years tinkering with general engineering etc.

all the functional systems i have built have been royer self resonant circuits based on the mazilli flyback driver. whereas these are simple to construct i found them to be wildly unpredicatable and totally uncontrollable – they either work or they blow up, spectacularly.

the experimentation has clocked up an almighty bill over the years and i still do not have a practical system.

i have sought the advice and help a various genii in the electronics department to develop the next version but in all honesty i think now is the time to shell out £600 on a chinese LH15a 15kw induction system and see if i can use the insulated tilting crucible with that. its a big gamble but i have seen one of these machines with a small graphite crucible melt iron to pouring temperature in about 30 seconds. My experience leads me to believe that no matter how small the induction circuit is, if the crucible is very well insulated then it will eventually get any of the common metals to melting and pouring point.

my interest in small scale induction melting stems from the noise, fumes and space required to run a gas/oil foundry. if you dont have a spare outside shed or an enormous flue in the workshop then burning gallons of fossil fuels simply cant happen. and then there is also the fossil fuel issue, say what you like about climate change, cleaner melting has to be better.

during the periods when my system has been on the button it was an absolute joy to use, quiet, clean and to my mind much safer. instant shut down, no lost heat to speak of, no actual fire, no fumes and with a tilting crucible there is no lifting of the pot full of molten iron which is for sure the exciting bit but also the most dangerous. i would dearly love to have a safe, reliable and useful induction furnace but my incling is that the homemade version simply will not ever be that unless you spend big bucks and heaps of time.

i think china has done all this work and appears to be very cheap. how reliable these boxes are is another question.

There are blacksmiths that use induction heating. But they have a serious handicap when compared to combustion forging. The dimensional volume of heating.

Not particularly well suited to reheating a small much less large scroll. And rather than the full volume of the forge at relatively even heat (in theory and based on design) the work has to be manipulated through the field in an attempt to get even heat. So it lends itself to some processes but is inappropriate to others. It lacks flexibility.

You certainly won’t be burning your steel because you have too many irons in the fire however

The circuit boards of these 2.5kW Chinese ZVS Induction heaters don’t seam too complicated, but I have not seen anyone copy one; nor seen anyone explain exactly how they work in layman’s terms, let alone scaling one up to 15kW. Agree with Richard on this one “One sign of a truly skilled and knowledgeable person is that they can make themselves clearly understood to just about anyone”.

Please be kind and respectful to help make the comments section excellent. (Comment Policy)

This site uses Akismet to reduce spam. Learn how your comment data is processed.

Electric Induction Furnace By using our website and services, you expressly agree to the placement of our performance, functionality and advertising cookies. Learn more