International cable manufacturer and supplier HELUKABEL recently partnered with dredging and marine construction company Callan Marine to power their new General MacArthur dredging vessel.

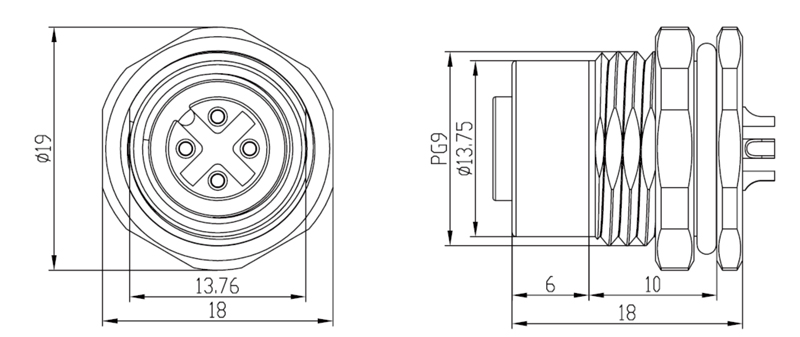

Galveston, Texas-based Callan Marine dredges for both private and public clients throughout the United States to restore and maintain the required depths and widths of main navigation channels, smaller transportation waterways, docks, and berths. After all, large shipping vessels can only navigate waterways and ports if silt and other debris carried by currents is kept clear from their seabeds. Otherwise, ships could run aground and get stuck. Cable Gland Pg 9

The new 295-foot (90-meter) cutter-suction dredger called the General MacArthur has three diesel engines that together output 24,000 hp. The engines provide the energy necessary to drive two 6,000-hp electric motors that in turn run deck pumps and two other 2,500-hp electric motors — one for an underwater pump and the other for a cutterhead. The underwater pump and cutterhead motors require specialty cables since they are totally submerged in saltwater all the time. The cables were designed to mitigate the electrical nuisances that are commonly found with variable frequency drives that power the motors, especially given the power requirements to maximize the dredger’s suction and discharge capabilities.

International shipping operations rely on canals and waterways deep enough to let cargo ships bearing valuable cargo pass without snags. The 2021 Suez Canal blockage caused by one container ship running aground cost the world billions of dollars in trade each day. The General MacArthur dredger (outfitted with HELUKABEL cabling solutions) works to keep such waterways free.

Crew accommodations include a galley, gym, TV room, laundry facility, conference room, and engineer’s office. Yet other accommodations include 33 beds, captain and chief engineer staterooms, and bathrooms — all with their own power needs.

An Italian electric-motor manufacturer connected a Callan Marine engineer designing the dredger with HELUKABEL; the motor manufacturer suggested HELUKABEL because they’d previously worked together on many successful projects in Europe.

Besides maintaining shipping channels, Callan Marine’s work replenishes beaches and recreation spaces. Adding dredged material to shorelines also protects coastlines from storms such as hurricanes. Shown here is the General MacArthur working in Port Neches, Texas near the Louisiana border.

HELUKABEL began the cabling design with the underwater pump and cutter motors power section. “One of the biggest challenges in building the General MacArthur was finding the appropriate submersible cable for the high-ampacity demand from these motors,” says Callan Marine automation manager Stanley Hamidjaja. The cables run through a structural arm (the ladder) that submerges both motors. It wasn’t possible to deliver the necessary capacity via a single cable for each phase.

“The team at HELUKABEL was very involved for over a year in submitting and resubmitting their proposal until they provided the cable specification and quality to our satisfaction,” says Hamidjaja. Working with Callan Marine’s engineering team, HELUKABEL provided eight AWG4/0 cables per phase for 32 cables total to provide necessary power. These cables have submersible ratings to 10 bar of pressure and the necessary American Bureau of Shipping approval required for cables on ships and offshore structures.

Shown here is a terminal box with cable and glands supplied by HELUKABEL aboard the General MacArthur.

The next challenge was to assist in designing a water-tight transition box for the system to terminate the VFD cables’ braided shields. Here, HELUKABEL proposed the design of the transition box to include KVA-XXLMS metal cable glands and KVA-XXLMS-E EMC cable glands rated for 10 bar or submersion to 328 ft (100 m). These glands accept cables with large outer diameters. What’s more, they accommodate custom inserts that deliver strain relief as well as a watertight seal between the gland and cable. The latter is especially unique as the system’s AWG4/0 cables have overall diameters beyond those serviced by standard inserts. The custom gland inserts were designed, manufactured, and delivered in less than eight weeks.

The General MacArthur has a 72-ft (21.9-m) beam and 8-ft (2.1-m) draft. After the General MacArthur came out of dock, it was sent off to the Gulf Coast.

Callan Marine is satisfied with HELUKABEL’s support.

“The General MacArthur is a game-changer vessel in the dredging industry, and we are proud to have HELUKABEL as a valued partner in providing quality, dependable cable,” explains Stanley Hamidjaja.

Other products to complete dredging-related tasks aboard the cutter included various sizes of nickel-plated cable glands capable of withstanding up to 10 bar as well as Category-7 data cables having Lloyd’s Register marine and offshore approvals.

After the General MacArthur came out of dock, it was sent off to the Gulf Coast for its first assignment to keep the vital shipping lanes near Texas clear for the continued safe passage of marine vessels.

Lisa Eitel has worked in the motion industry since 2001. Her areas of focus include motors, drives, motion control, power transmission, linear motion, and sensing and feedback technologies. She has a B.S. in Mechanical Engineering and is an inductee of Tau Beta Pi engineering honor society; a member of the Society of Women Engineers; and a judge for the FIRST Robotics Buckeye Regionals. Besides her motioncontroltips.com contributions, she also leads the production of the quarterly motion issues of Design World.

Browse the most current issue of Design World and back issues in an easy to use high quality format. Clip, share and download with the leading design engineering magazine today.

Top global problem solving EE forum covering Microcontrollers, DSP, Networking, Analog and Digital Design, RF, Power Electronics, PCB Routing and much more

The Engineering Exchange is a global educational networking community for engineers. Connect, share, and learn today »

Comet Gland Copyright © 2024 WTWH Media LLC. All Rights Reserved. The material on this site may not be reproduced, distributed, transmitted, cached or otherwise used, except with the prior written permission of WTWH Media Privacy Policy | Advertising | About Us